D&R Confectionery Solutions

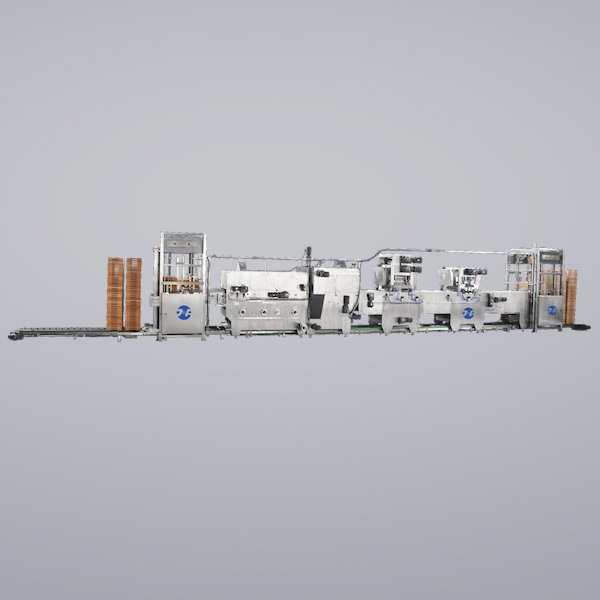

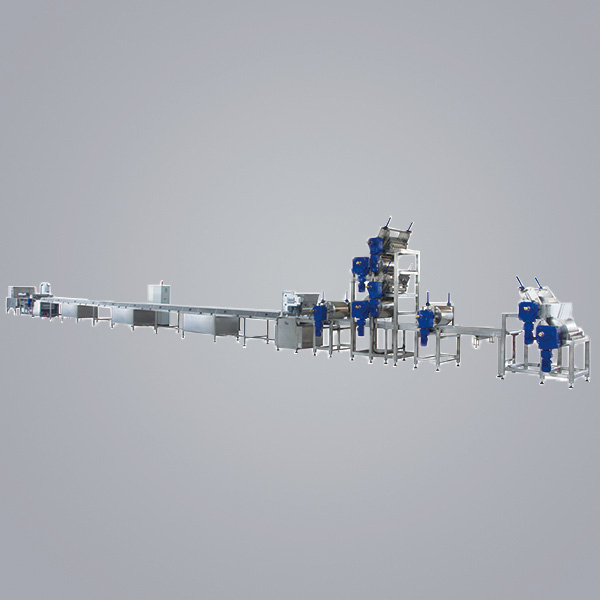

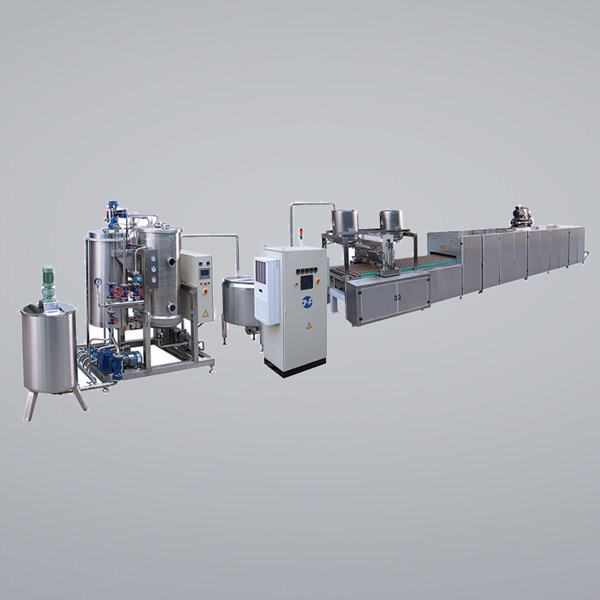

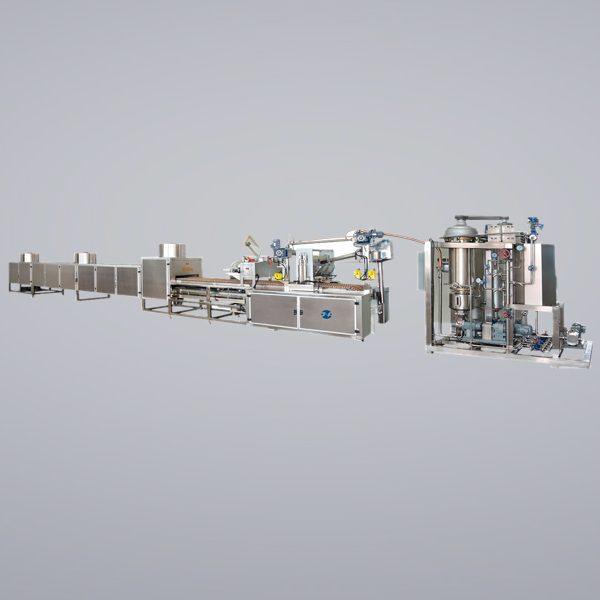

Featured Products

TOTAL SOLUTION

TOTAL CARE

PERFECT YOUR SWEET LIFE

When we started D&R Machinery we had one goal in mind and one goal only. That was to be that Chinese brand that delivers the highest end confectionery equipment in the world. Now in China, this isn’t a simple task, we are dealing with all kinds of corner cutting, cost saving and penny pinching manufacturers here on a daily basis. That didn’t stop us. You see when you have a goal to say that you want to be #1 in the world and let everyone know you put a target on your back that keeps you pushing forward. We can’t stand giving clients who trusted us with their business and delivery of their confectionery product line anything other than the best. We are fully comitted to delivering the best, and we’re with you all the way.”

Read More >WHY CHOOSE D&R

TRUST

Our customers are with us for the long-term, clients are buying our total-solution product lines to become long term partners. Customers need to know that we are there for them.

RELIABILITY

Our customers are with us for the long-term, clients are buying our total-solution product lines to become long term partners. Customers need to know that we are there for them.

LAB SERVICE

Our customers are with us for the long-term, clients are buying our total-solution product lines to become long term partners. Customers need to know that we are there for them.

News & Blogs

Hard Candy Moulds: Best Buying Guide

If you are thinking of opening a business of molds, then you have to decide first, will it be hard candy molds or chocolate candy molds.

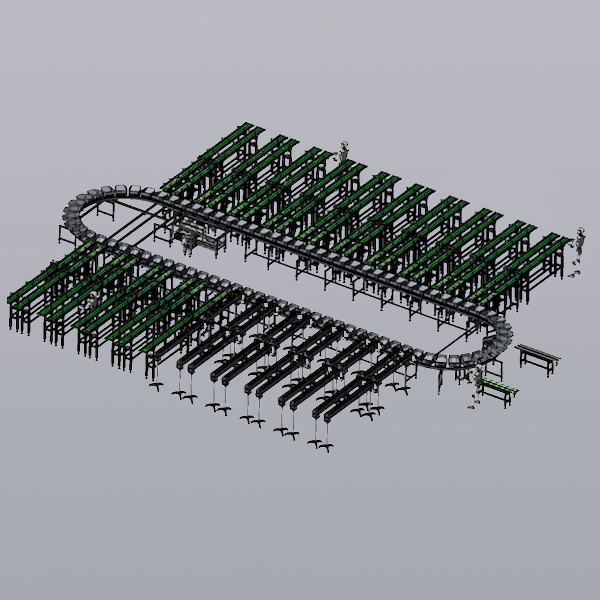

Warehouse Order Picking System and Its Types

It's critical to invest in a warehouse picking management system that works. Your warehouse's order-picking system can have a significant impact on the efficiency of your supply chain and overall business operations.

Chocolate Enrober Machine: All You Need to Know

A chocolate enrober machine is a device that coats candy or other food items with a layer of chocolate.It typically consists of a belt or conveyor system that moves the product through a tank of melted chocolate, depositing a thin layer of the chocolate onto the product as it moves.