Maltesers Production Line

D&R Machinery

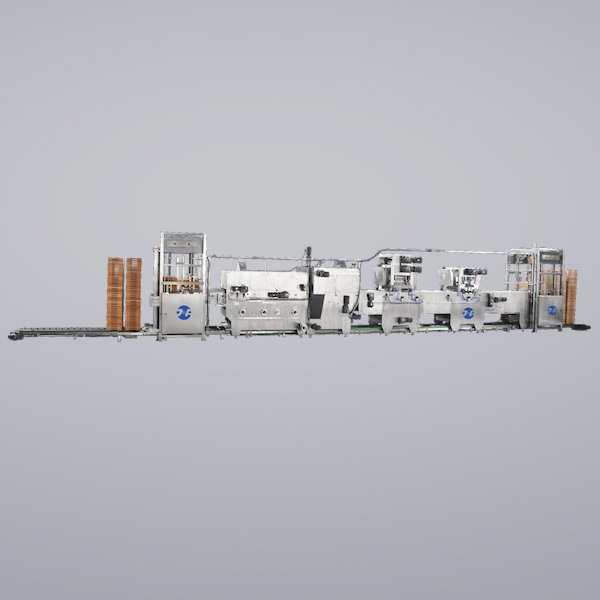

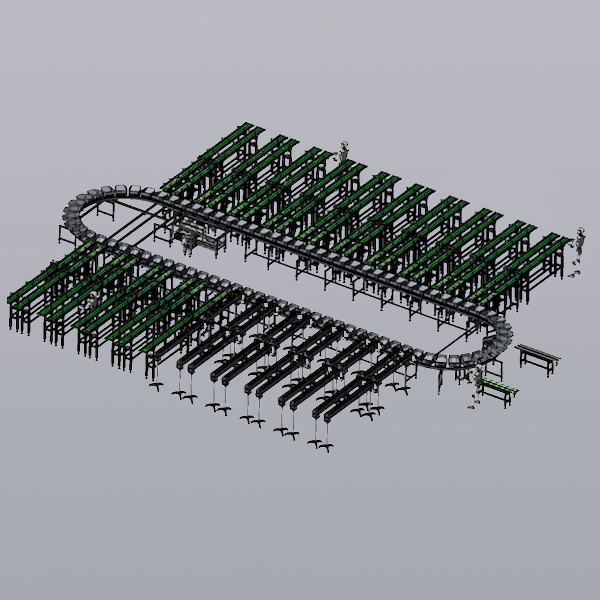

D&R maltesers production line especially producing maltesers.With high quality,easy operation,working reliable,with high output.The whole plant include kitchen system,maltesers plant,starch conditioning system,starch collecting system,product finishing and ancillary machinery.

Leave An Inquiry

Description

Maltesers Production Line

|

Production capacity(kg/h) | 1000(Depends on the shape of candy) |

| Power consumption(kw) | 252(Depends on the machine type) | |

| Steam consumption(kg/h) | 1200kg/h | |

| Steam pressure(mpa) | 0.8 | |

| Compressed air consumption | 7m3/min | |

| Air pressure | 0.8mpa | |

| Vacuum water consumption(m3/min) |

2 |

|

| Machine weight(kg) |

30000 |

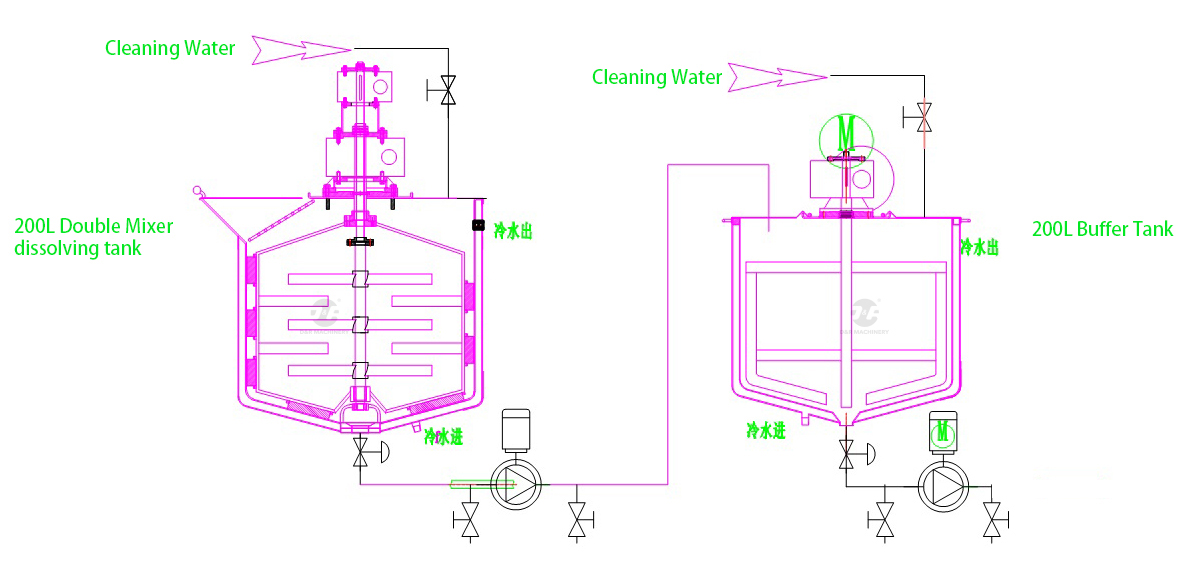

Kitchen System

The full system including a 200L double dissolving tank and a 200L buffer tank.

The full system including a 200L double dissolving tank and a 200L buffer tank.

Batter dissolving tank(Double Mixer)

Double mixing system, combines the use of one or two tools with the scraper, depending on a pre-set rotating ratio, to guarantee quality mixing in a class of its own .

Double mixing system, combines the use of one or two tools with the scraper, depending on a pre-set rotating ratio, to guarantee quality mixing in a class of its own .

Pre-mixing system with pump.

To pre-mix the batter and put it into the buffer-tank. Capacity is approx.200L.

There is the interlayer device for avoiding the high temperature.

For cleaning purpose , a separate cip pump is set close to this pump, and a drain-valve is next to it to drain the cleaning water.

SS304 mixing tank, jacket for cooling water; mixing stirrer with scraper (planetary mixing type); with safety switch, duckbilled inlet and safety net with clean ball; pneumatic butterfly valve fixed under the bottom of tank; with height adjustable stainless steel legs; motor with automatic speed control and double speed gear box,5.5kw.

Buffer tank

|

Capacity | 300L |

| Material | SS304 | |

| Jacket | With cooling water jacket | |

| Mixing motor with gearbox | Fixed speed mixing | |

| Valve | Pneumatic discharging butterfly valve |

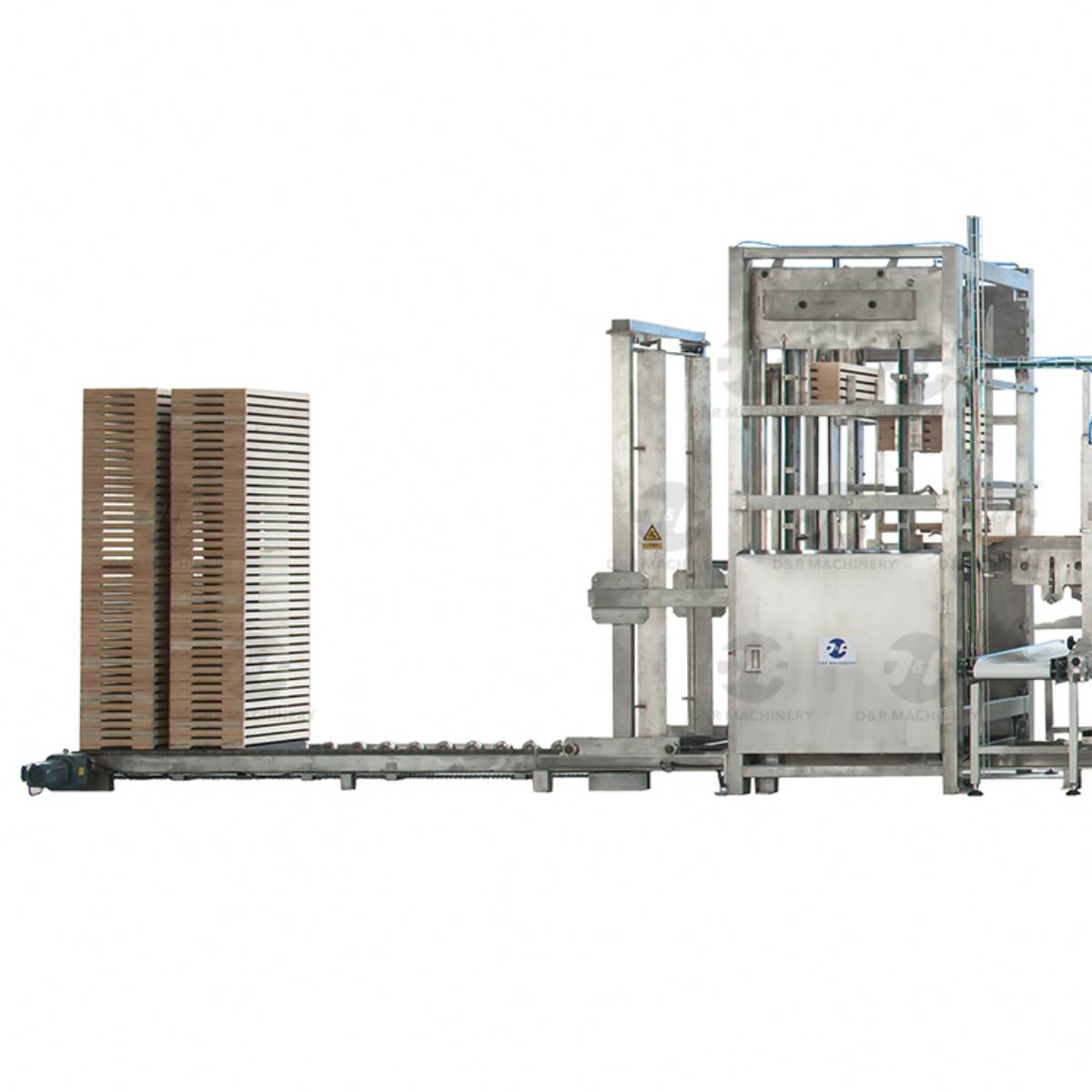

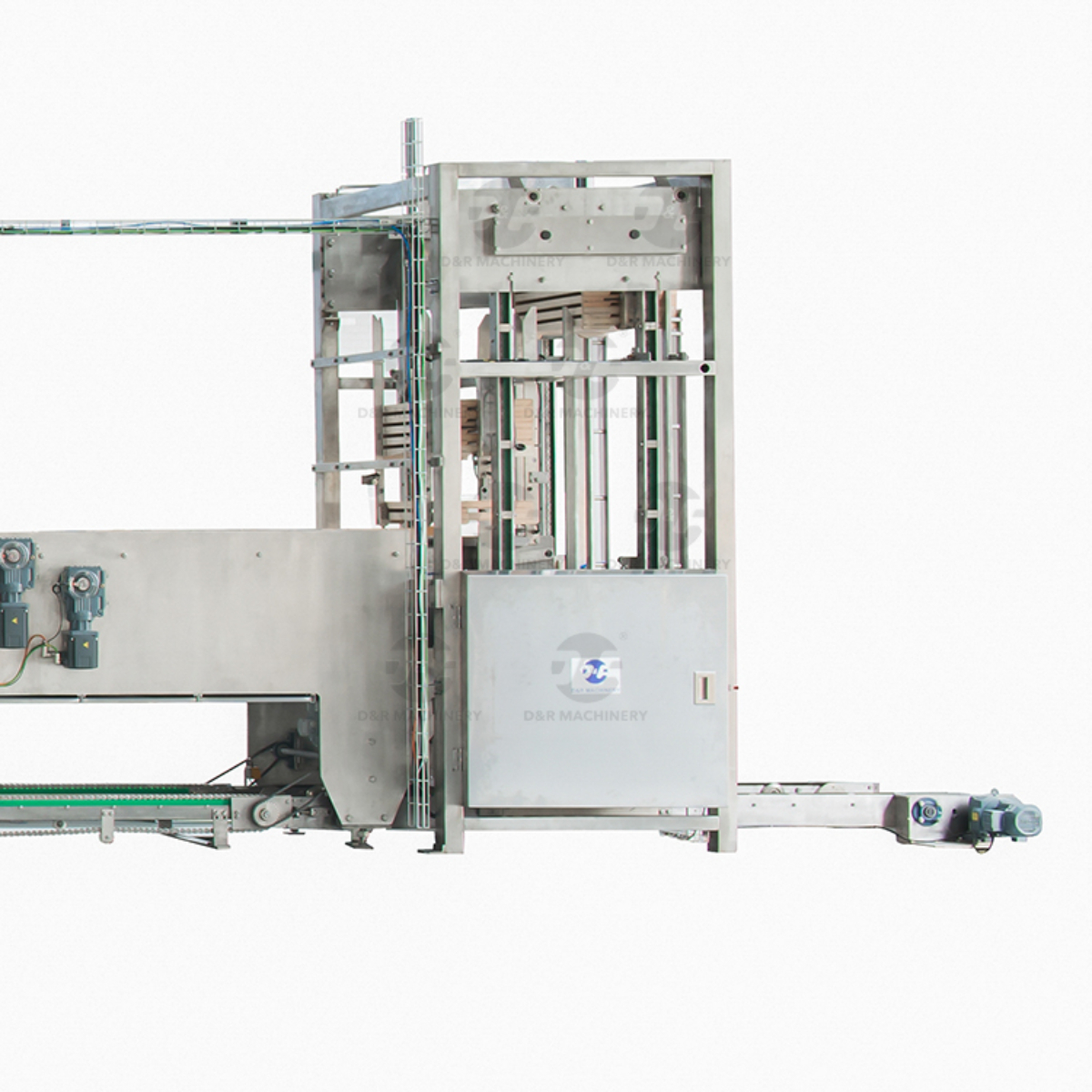

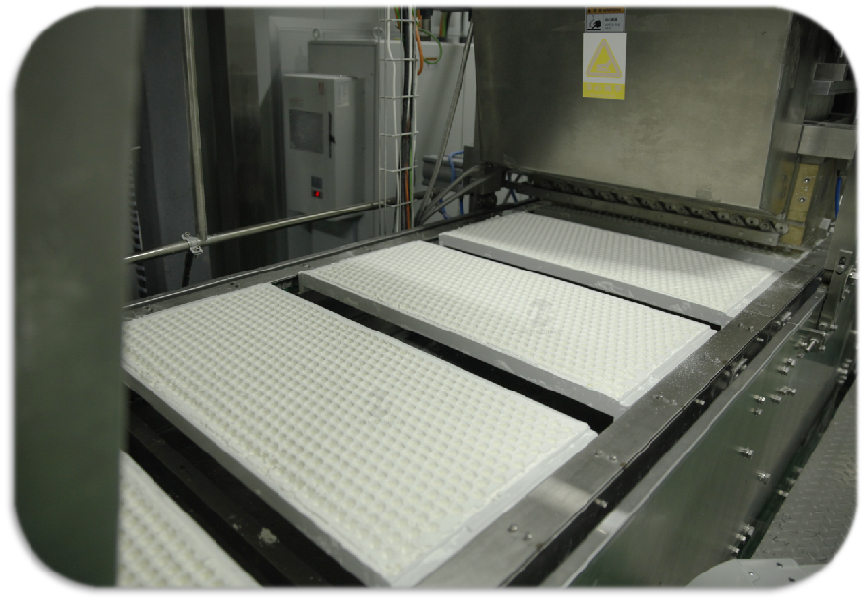

Tray feeder

The trays will be stacked (4pcs trays per stack) and lift to the tray feeder. The Feeder is equipped with input roller track on which the operator places the pallet. Standard entry method is from the end of the track. Full stack height gates are provided for positive, safe stack feeding. Full stack-height rollers ensure the stacks are straight when entering the Feeder.

The gates close behind the stack and remain closed until the whole stack is safely de-stacked. The stack is first de-stacking into groups of 4 trays which are then separated into single trays. The de-stacking conveyor moves continuously. The full system speed controlled by one servo motor.

STARCH SECTION

STARCH SECTION Servo depositing system

Servo depositing system

At each position of the pumps, depositing the material inside the trays with FULL TRAY depositing system.

Typically the pump on the first position is used to center of “MALTESERS”. The pumps use valve bar ensuring identical delivery of mass to each piston and nozzle, as well as simplicity of operation and low repair costs. The complete pump body made by stainless steel 316. The valve bar running is effected by a conventional hydraulic cylinder, connected by connecting bar. The valve bar made by smithing albronze, more stronger.

The Depositor settings for deposited volume such as the length of the piston stroke as well as the timing of the valve bar are effected through adjusting on the touch screen parameter. The precise adjustment of the volume by motion controller.

Two important parts on the depositing pump, namely the Nozzle plate and the piston bar, are designed to deposit a specific product. Charge of product often makes it necessary to change these parts which because of their design can be changed within minutes. Depositing pump supplied on the machine should with one nozzle plate and one piston bar, Additional nozzle plates and pistons bars are offered separately below. Tray stacker

Tray stacker

Construction is similar to the feeder. A group of up to 4 trays is accumulated in the stacker magazine. Stacker clamps carry the groups of trays in a smooth, continuous motion and form a complete stack on the pallet at the discharge side of the section.

The empty pallets are automatically delivered from the feeder to the stacker by the pallet underfeed conveyor, once the stack of tray is complete, the pallet is advanced to make room for the next stack. When two stacks are complete, the pallet is advanced further onto the roller track from which it is transported to the drying room by small cart.

Curing Room

The stack after depositing with products, then be sent into hot drying room(over 90℃) for baking the center to required form and taste. dring room is key point of processing for “Maltesers” center production. The system consists on rooms, machine, piping, automatic control and so on.

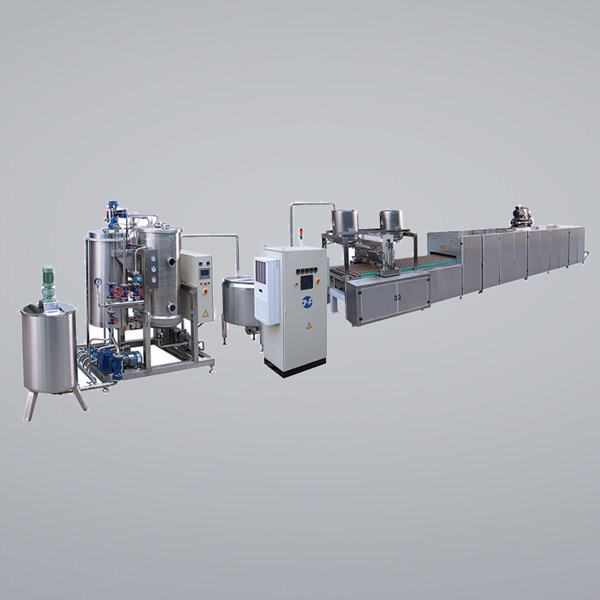

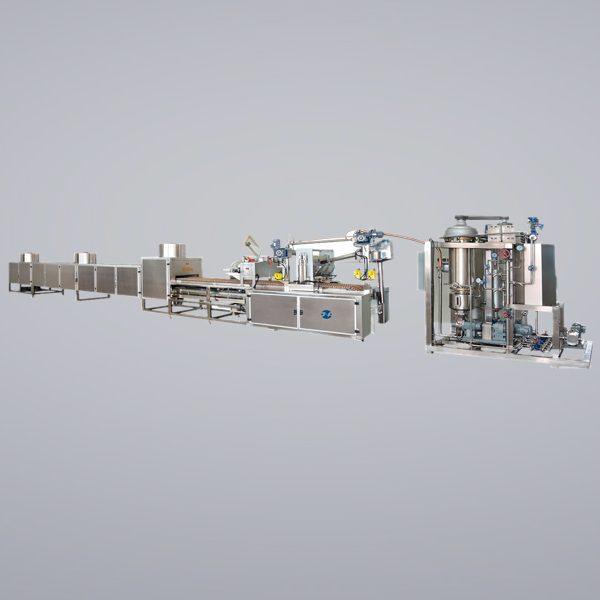

The budget of project will be given after design of workshop.  Chocolate Belt Coating System

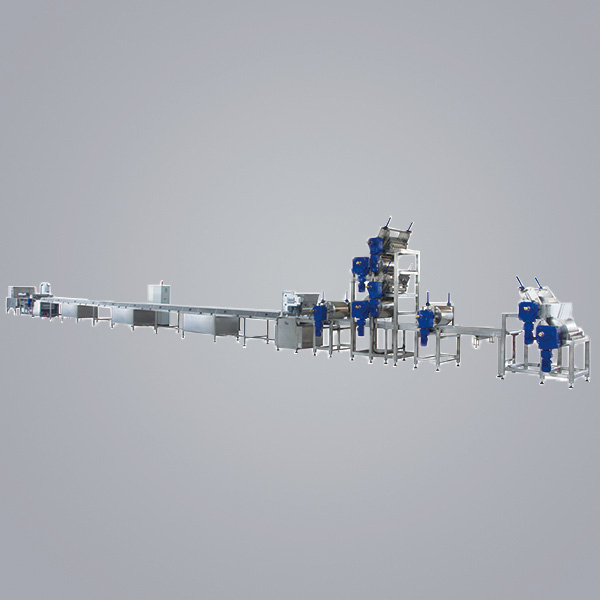

Chocolate Belt Coating System

This machine is an advanced equipment for chocolate coating, especially for chocolate bean, melon, nuts, dry fruit, marshmallows and so on. The machine is automatically controlled by PLC with touch screen, installed with system of recipe save and automatic weighing. The flowrate of chocolate mass, the capacity of cold wind, the speed of mesh belt moving is adjustable.

Process time: 40-60min/batch, humidity of air should be 45-55% (The process time is based on the material of coating layer and products which need to coat, temperature of air and humidity inside of machine.).The weight of coated products is about 250kgs. Characteristic

Characteristic

1. Stainless steel structure for wash easily.

2. Full automatic and exact chocolate coating metering valve.

3. Jacket chocolate sprinkler system with tip cleaner to make sure the nozzles will not be blocked.

4. There are lights in the machine.

5. Convenient and detachable system for recovery of scrap material.

6. There are four legs with automatic weighing system(loadcell).The max.weighing is 250kgs.

7. There is a chocolate mass adjustment valve to control the flowrate of chocolate mass.

8. Power of main motor is 3KW. Most of parts including the frame, cover and the parts which contact with products(except plastic conveyor belt) are ss304.

9. Electric components are Siemens or Schneider brand. Control system is Delta brand(PLC).Chinese brand motor with gearbox. Pneumatic system is Airtac.

10. It should works with one 500L chocolate storage tank, one chocolate feeding pump(speed adjustable), chiller, polishing machine or pan,jacket pipes and hot water tank.

D&R Machinery are professional confectionery machine manufacturers with over 20 years in the business operating at the highest industry standards.

We've built a reputation on engineering, designing and delivering high performance total-solution confectionery machinery to clients with absolute precision around the world.

The confectionery machinery industry is a small world, and we've slowly become leaders in innovation and creative solutions for clients from all walks of the industry. D&R Machinery has become synonymous with one word and one world only in the confectionery machinery world and that is 'total-solution', that is end to to end turn key production of the highest quality confectionery machinery in the world.

Becoming the D&R Machinery you see today starts and ends with the word 'care'. You don't become the best without a plan that ensures our clients achieve the success they desire, and at D&R Machinery it starts with care and ends with trust, reliability and innovation.

1.Q:Where are your company?

A:D&R office is located at F12, Shanshan Plaza, Yinzhou District, Ningbo, China.

D&R factory is located at Xishanli Village, Qiantong Town, Ninghai County, Ningbo, China.

2.Q:Are you direct factory?

A:We are both manufacturer and trading companiesno one knows more about our products than we do.We can provide the best quality equipment and the most affordable price, and according to your request, we can more quickly provide the corresponding service Scheme.Certainly,We welcome you to come visit our factory.

3.Q:What are your main products?

A:All kinds of chocolate making machines, candy making machines,Swiss roll and layer cake production line, cadny bar production line and their packing machines.

4.Q:Do you have gurantee for your product?

A:As a factory, no one knows more about our products than we do.We have a fairly strict standard for our products.Our products have CE certification and EAC certification.

5.Q:How can we contact you?

A:Here is contact information:

Contact company: Ningbo D & R Machinery Co., Ltd

Website:www.dr-machinery.com; www.sweetmachinery.com

Direction phone:+86 574 88304275; +86 18057458607

Fax:+86-574 87839559

Specifications

Featured Products

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message