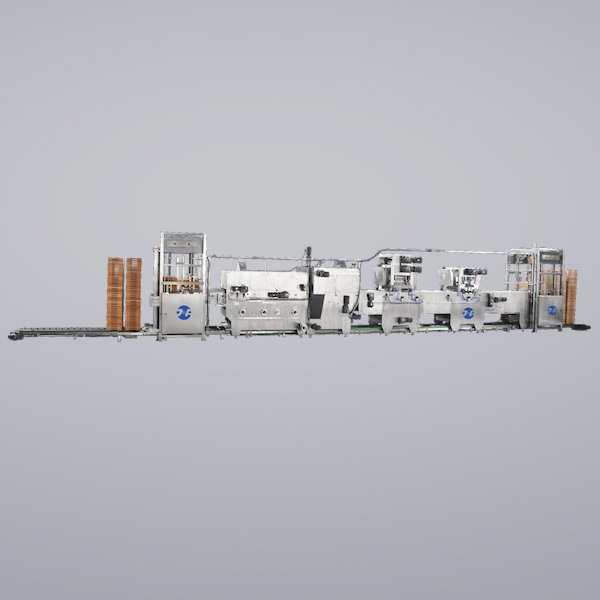

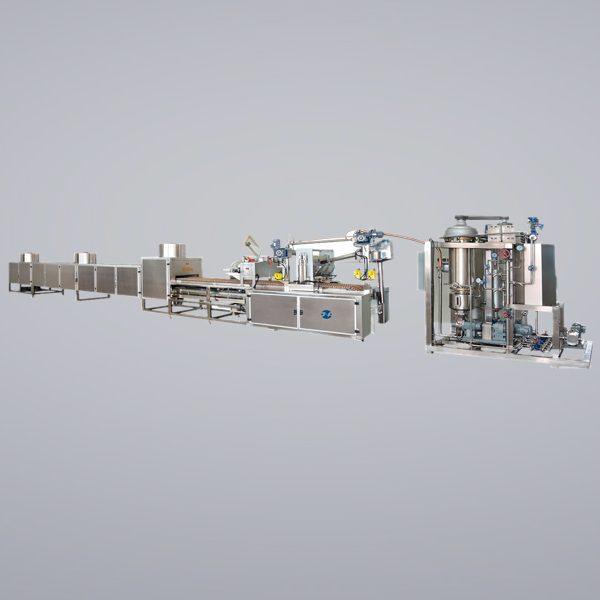

Starch Mogul Gummy Candy Production Line

D&R Machinery

D&R mogul line is an advanced and fully automatic production line for gummy candies. High quality, easy operation, stable run and large capacity.

Leave An Inquiry

Description

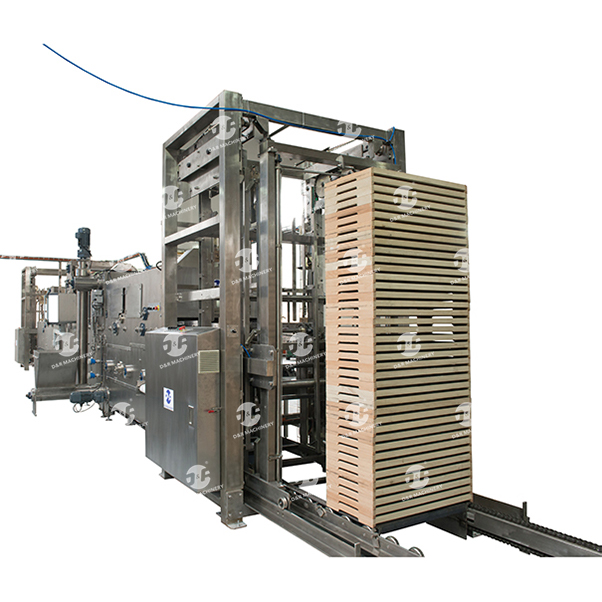

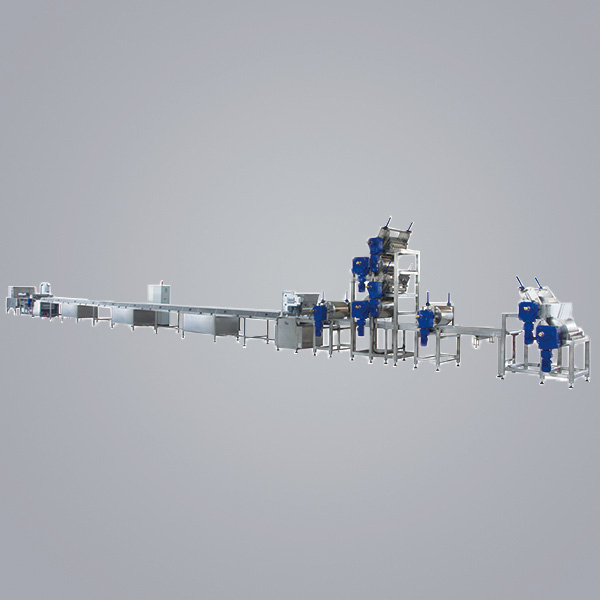

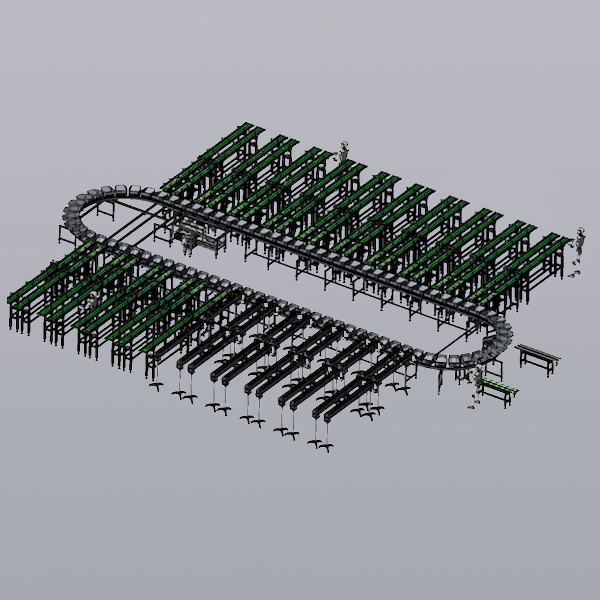

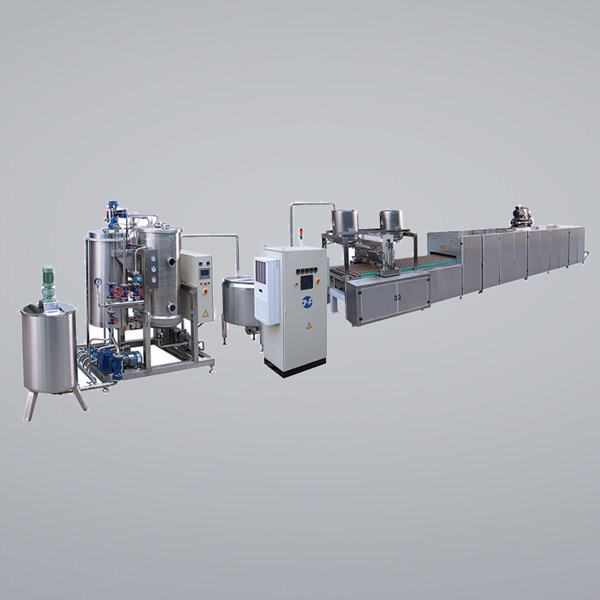

D&R mogul line is an advanced and fully automatic production line for gummy candies. High quality, easy operation, stable run and large capacity. The whole line includes a kitchen system, a mogul line, a starch conditioning system, a starch collecting and recycle system, a product finishing and ancillary system. Whatever your production requirements are, D&R will give you the best solution of starch mogul.

Larger Capacity and Lower Energy Consumption

- 1000~2500 kg/hour and 22~32 trays/min capacity lager than average of 1000~1900 kg/hour and 15~25 trays/min

- 360° warm keeping greatly improves sugar degree, reduces tailing defects and shortens drying time

- Tanks are insulated to save energy

- Pipeline systems automatically remove residue

- New generation starch conditioning systems optimizes air supply and circulation

Remote Monitoring Module

Machine data can be monitored and analysed remotely to facilitate installation and reparation. The powerful functionality module helps reducing downtime significantly. With this advanced and handy tool, D&R can support clients 24x7 much more easily.

Other Advantages

- Suits for producing gelatin base candies, pectin based candies, foamed candies, marshmallow and fudge etc

- Easy operation with one click parameter setting

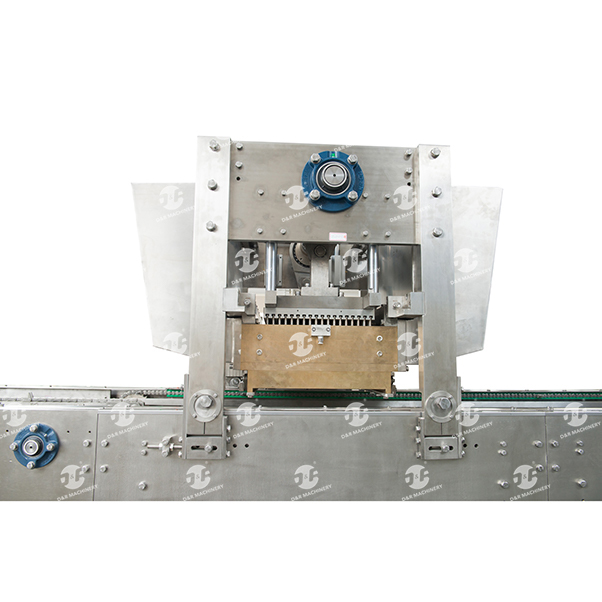

- High accuracy, stability and quality achieved by using top brand components and digital servo controllers

- Food grade 304 stainless steel used

- Easy and fast switching among double color, spray color, center filling and etc

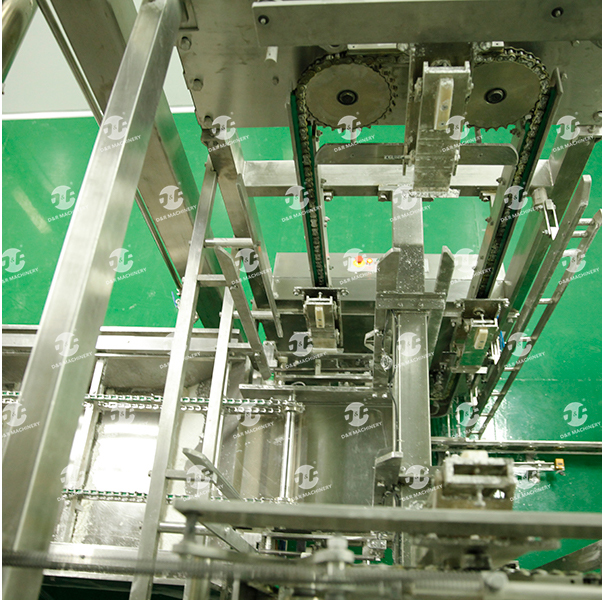

- Minimized starch pollution for better working environment

- Factory space saved by compact structure and customized layout design

- Easy and quick cleaning by one click setting feature

- Replacement of depositing accessories can be completed in minutes

Feature:

- Full automatic, keep recipe safe, ensure the high quality of products, and save labor costs.

- Stable run and large capacity.

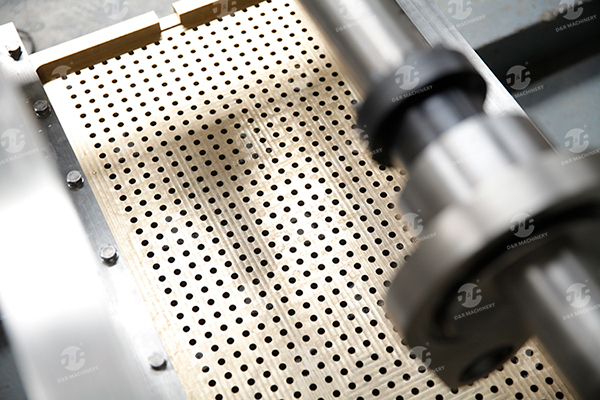

- Servo driven depositing system, suitable for single& double color gummy, multi-layer gummy and center filling gummy etc.

- No brush design and strong magnetic filter, ensure the safety of products.

FAQ :

1. How do you mass produce gummy candy?

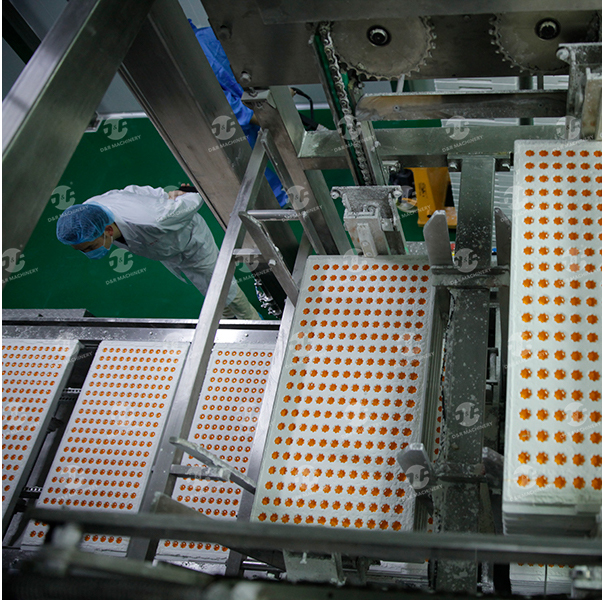

Small quantity gummy can be done by home made, but if bulk production should use full automatic starch mogul line for producing the gummies. Material be prepared and dissolved automatically by machine, cooked to required temperature and brix, then depositing into the required shape cavities of starch moulds, then send into curing room waiting for required time till to right brix, send back to mogul for cleaning the starch, coating by oil or sugar.

2. How to make aerated products on starch mogul line(gummy making machine)?

Gelatin solution send to D&R automatic aeration machine, then depositing by starch mogul line (gummy making machine). Like Aerated Banana, Double layer products.

3. How are gummies manufactured?

1. Dissolve gelatin and other ingredients into syrup for use.

2. Then send to D&R full automatic weighing and dissolving system automatically which controlled by PLC.

3. Send to D&R automatic cooking system and heating to required temperature.

4. Comcentration by automatic vacumming system to right brix.

5. Cookered sugar slurry be sent to D&R automatic color, flavour, acid dosing and mixing system for mixing with required color and flavour and waiting for depositing.

6. Ready material send into the hopper of D&R starch mogul line (gummy making machine) automatically, depositing into the starch cavities, full machine working automatically.

7. Send to curing room for drying.

8. Send back to D&R starch mogul line (gummy making machine ) cleaning the starch, coating by oil or sugar .

9. Packing into required box or bag for selling.

4. What are gummy products made from?

Gummy mainly is made by gelatin, pectin, glucose, sugar and other ingredients.

5. How do you make gummies that don't melt?

If gummy only adding gelatin easy to melting, the melting temperature at 32-35 degrees. If the hot season, add modify starch or pectin for keeping the hot resistance, the melting temperature at 40-45 degrees.

6. How are different types of gelatin used in the production of gummy?

Fish gelatin, normally use TILAPIA skin or scale, it use for JEWISH market. For normal market, fish gelatin for phamarcy and comestic beef gelatin, normally use for halal gummy, also use for normal gummy.

Pig gelatin, mainly use for Eastern Asian market, like CHINA, KOREA, JAPAN and EUROPEAN MARKET, also use for pharmacy and comestic market .

7. Can vegetable glue be used in gummy production?

Yes, like carrangeenan, pectin, agar, arabic gum widely use for gummy production, also suitable for vegetarian products and health products.

8. How is taste difference of gummy in difference market ?

Different consumption habit makes the different taste of markets. There are 2 big difference gummies in the market .

- Eastern asian market , people likes more soft gummy , so it should putting less gelatin .

- Middle east, European market, North American people likes hard and more biteable products, so it should putting more gelatin .

Specifications

| Capacity | |

| Air Pressure | 0.8 MPa |

| Vacuum Water Consuption | 2 m³/min |

| Dimensions (L*W*H) | 22000x2000x3000 mm |

| Power | 97 KW |

| Steam | 850 Kg/H, 7~8 bar |

| Compressed Air Consumption | 400 m³/h |

| 4 Degree Cooling Flux | 315 Kg/min |

| Weight | 20,000 Kg |

Featured Products

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message