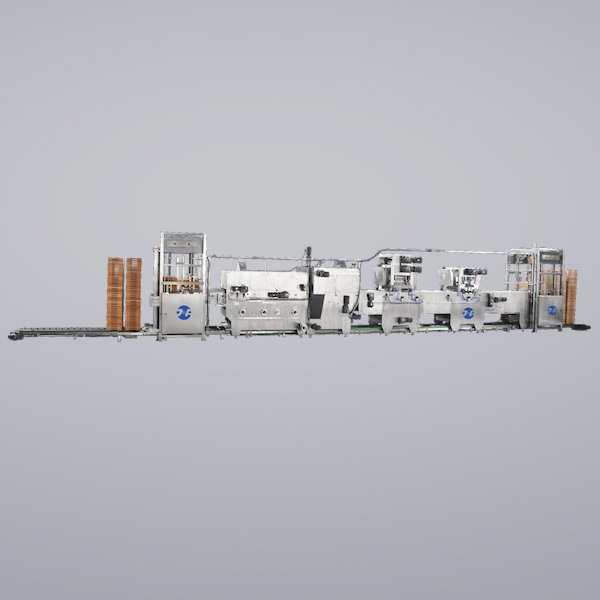

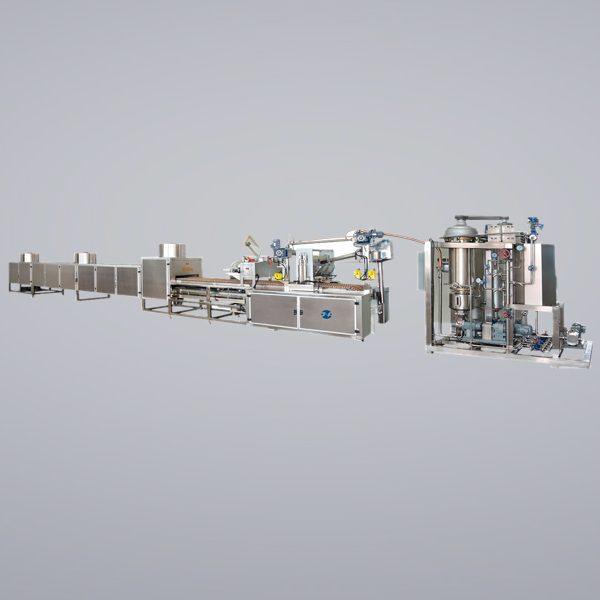

Chocolate Production Line Chocolate Moulding Line

D&R Machinery

The most popular type of chocolate production line is chocolate moulding line. This chocolate moulding line can produce pure solid chocolates, chocolates or bars with big center filling, double or four color chocolates, amber or agate chocolate and biscuit chocolate. It cab work in the fully automatic mode with a capacity of 100 - 300 kg/hour.

Leave An Inquiry

Description

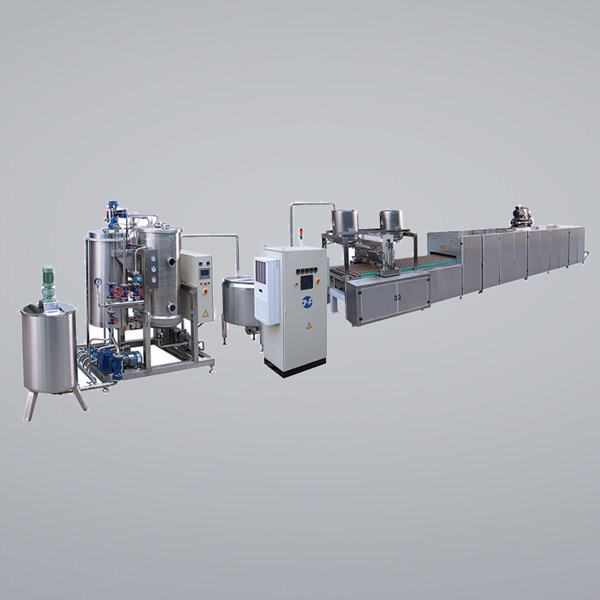

Large Capacity and Accurate Control

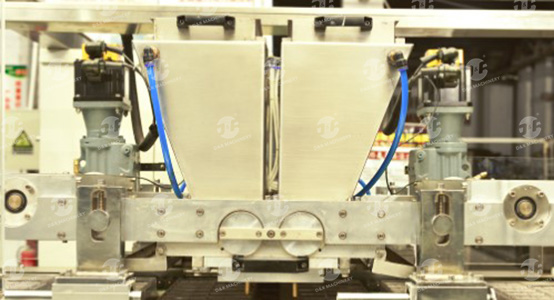

D&R's chocolate production line has a larger capacity, 18 ~ 20 moulds/min, than average. It uses digital servo control with one click settings so as to achieve high chocolate quality.

Remote Monitoring Module

Machine data can be monitored and analysed remotely to facilitate installation and reparation. The powerful functionality module helps reducing downtime significantly. With this advanced and handy tool, D&R can support clients 24x7 much more easily.

Characteristics

- Top brand components and servo controlled

- Food grade 304 stainless steel used

- One click setting for easy and quick cleaning

- Minimised pipeline bends

- Replacement of depositing accessories can be completed in minutes

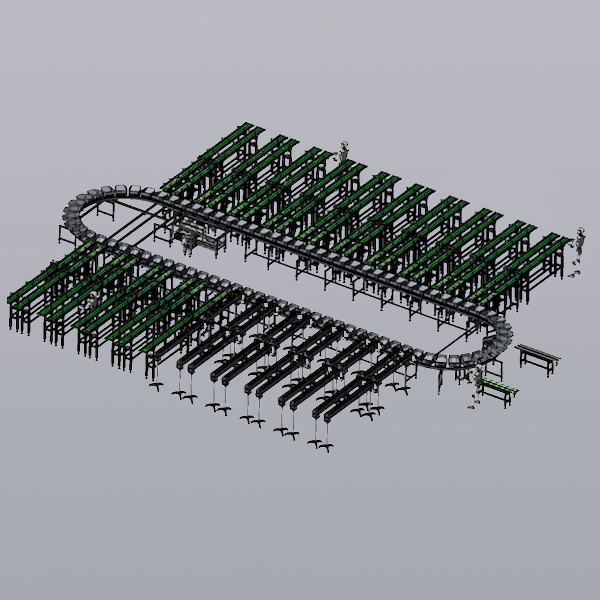

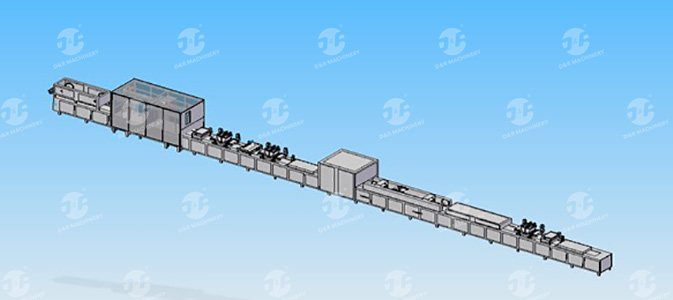

- Factory space saved by compact structure and customised layout design

- Easy and fast switching among double color, spray color, center filling and etc

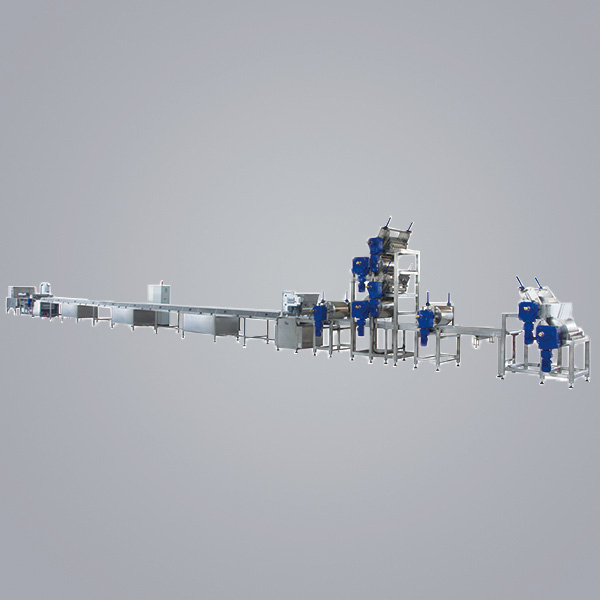

Chocolate moulding line is the most popular type of chocolate production line. This whole chocolate moulding line includes mould heater, depositing, mould vibrating, cooling, demoulding system, discharging conveyor of products. Suitable for moulded chocolate production with or without various add-on equipment.

D&R chocolate moulding line can be customized to your facility, production requirements and to produce the perfect chocolate product for your market. You can also choose from flexible options like automatic or semi automatic mode, one or two or three heads and etc. An automatic biscuit feeder can be added to make chocolate with biscuits.

Values for Production Line Owners

- Small investment. We are the leading manufacturer in China for confectionery equipment with own design team and manufacturing facility. With our years experience working with clients all over the world, we know how to build the most cost effective solutions for you.

- High speed, high efficiency, highly stable and longer life. We use European brand servo motors and electric parts in our servo driven system, motion controller and other equipment. The whole machine is built with stainless steel.

- Total care. Our unique remote support capability, enabled by dedicated hardware and software, can help you anytime anywhere through internet. The experienced engineering team, fluent in English speaking, will strongly support you from design to production. And the mobile design of depositing head makes it easy to clean and maintain.

- Installation risk free. Our engineers will be on-site for installation and deliver the training covering details for your team. We will make sure your production a success.

- Highly flexible. Various products can be produced after changing nozzle plate like one shot, solid, mix and multi layer. Large center filled products, more than 70% center filling, can also be made. The max size can be designed according to the mould size, the min 3 gram with soft filling. Packing can be directly connected.

FAQ:

1. Why choose D&R's chocolate production line?

- Small investment bugdet

- Compact design of machine and stable running

- Various products can be produced on this plant after changing nozzle plate

- Large center filled products can be made with more than 70% center filling

- Digital controll and easy for operation

- European brand servo motor used for higher stability and longer life . Easy to get the replacement parts locally.

- Motion contoller makes the machine intelligent

- Remote software service from China by internet

- High speed and high efficiency

- Removable design of depositing head, easy to clean and maintain

2. What kinds of products can be made with this chocolate production line ?

One shot products, plain chocolate, mix chocolate, multi layer (by adding depositing head), biscuit chocolate.

3. How do we support our clients for installation and after sales?

- D&R's engineer team will be on site for installation.

- Clients' engineers can be trained remotely.

- The production line can be monitored and operated by the remote monitoring system.

- Guarantee for 1 year and whole life service

4. What are the max and min sizes of products can be made?

Max size can be designed according to the moulds size. Min is 3 gram with soft filling.

5. What's the packing solution?

Packing equipment can be directly connected to the line. The chocolate can be automatically fed to packing machines or fold wrapping machines which can be supplied by D&R machinery.

Specifications

| Capacity | 18 ~ 20 moulds/min |

| Mould Size | Customised |

Featured Products

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message