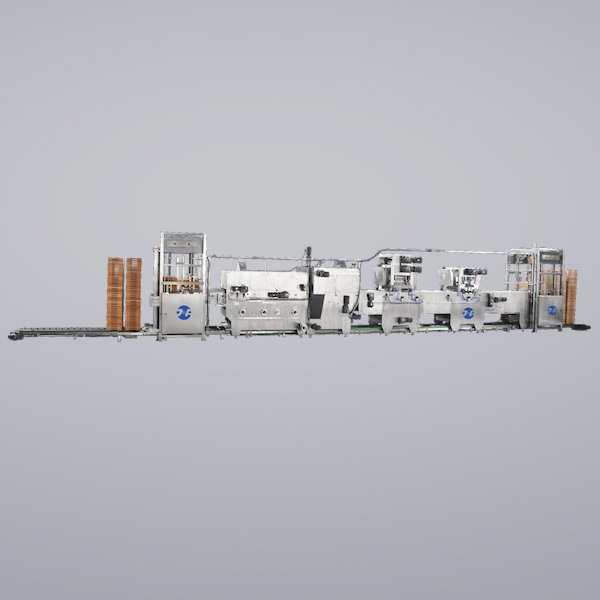

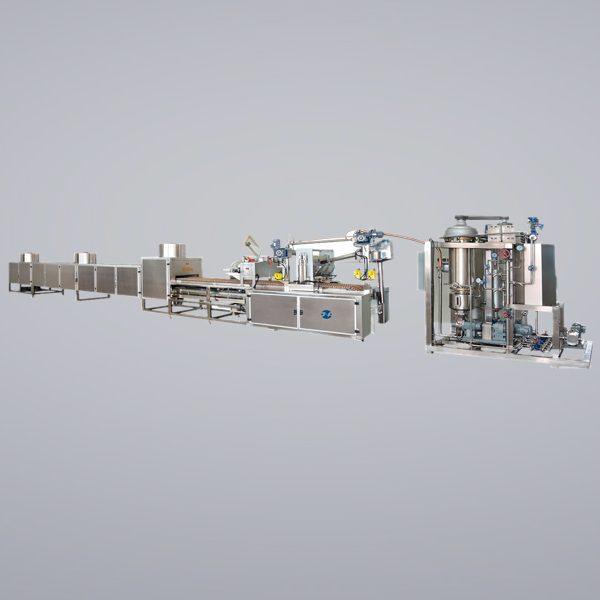

Marshmallow Production Line

D&R Machinery

Marshmallow production line, capacity 300-500kgs/hour

Leave An Inquiry

Description

Marshmallow production line, capacity 300-500kgs/hour

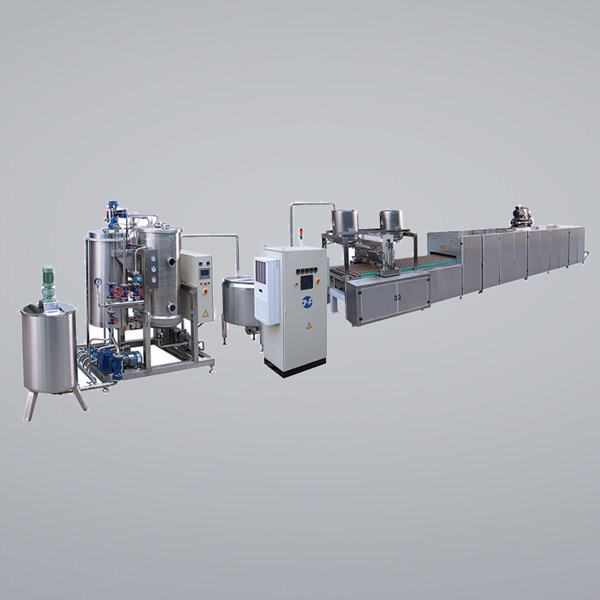

Kitchen system

1 Gelatin solution

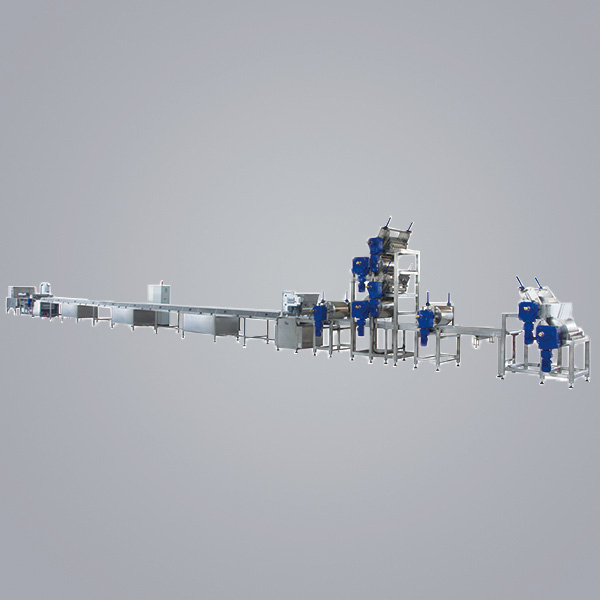

1.1 Gelatin dissolving tank 2 pcs

- Capacity 200L, with s.s 304 material for full tank, jacket with hot water to keep warm.

- Siemens inverter controls the mixing speed, with temperature display.

- Mixing motor: (Chinese)

- Pneumatic discharging butterfly valve

- With automatic water measure system (water meter type)

- 2pces dissolving tank with alternative working

1.2. Discharge pump 1 pc

- 40TL ,Lobe pump with sew motor

- With warm keeping jacket

- Capacity: 3tone/hour.

1.3. Simple weighing tank

- With SS304 for full tank, hot water jacket.

- 2. AFD-II Automatic weighing and dissolving system

- (one weighing and mixing tank and one dissolving tank).

It includes a hopper for holding sugar, a screw to send sugar to automatic weighing and mixing tank. There is safety control valve on each liquid material tank, the diameter of glucose valve is 50mm, others are 32mm or 25mm. 1set.

1.1.1. The weighing system consist of weighing frame, weighing sensor(3pcs,meters of liquid materials) and transmission device(sugar) etc.

1.1.2. Material tanks(280L)

Jacket and heated by hot water( about 700mmX650mm, cylinder shape with cone bottom and the thickness is 2.5mm) with mixer(1440rpm), discharging valve(φ76mm),etc.

1.1.3 frame of tank

1.1.4 Pneumatic system

1.2.1 dissolving device(320L)

1.2.1.1 dissolving system: one tank to be 320L,cone shape of bottom and top.The wall thickness is 2.5mm. Mixer:1440rpm.There is a liquid level sensor.There is a discharging valve and tee(manually).

1.2.1.2 Temperature control system: temperature sensor and temperature control units.There are coils in the tank for heating with steam.

1.2.1.3 Pneumatic system

1.2.1.4 Rotor motor

1.3.1 Electric and pneumatic control system

- It is controlled by PLC. It can store the recipes. There is a touch screen to operate.

- Material:The parts which touch with products are SS304(AISI304), wall thickness is 1.5mm

- Frame is stainless steel.

- Electric cabinet is mild steel with paint.

- Motors and gearbox: SEW. There is one rotary pump

- Electric components: Schneider brand(factory in China)

- PLC and touch screen: Mitsubishi PLC and Weinview touch screen.

- Cylinders: Festo

- Liquid level: NEGELE and Beijing Airline in China

- Pipes and valves: ss304

- Drain valves and angle seat valves: Spirax Sarco.

- Other valves: Chinese brand(like butterfly valves)

- Rotary pump:SEW motor and gearbox, Chinese pump.

- Total power:14.7kw.

- Power supply:380V,50Hz,3 phase.

3.two cooling tanks(jacket, to fill cooling water) 2pcs

- Capacity:500L, with SS304 for full tank

- Jacket and cooled by cooling water from water chiller.

- With high and low level sensors.

- Mixing motor with gearbox: fixed speed mixing(Chinese brand motor)

- Pneumatic discharging bufferfly valve.

4. Rotor pump

- 40TL, rotor pump with SEW motor.

- With Siemens inverters to control its speed

- With hot water warm keeping jacket

- Capacity: 3 tons per hour.

5. Aerating system

5.1. Buffer tank

- tank with a capacity 300L

- with one spray ball and seal cover with a human hole for check

- through the jacket of tank a heating medium will be pumped, this is to keep the syrup in the tank at a desired temperature

- outlet valve at the bottom 2”, pneumatic operation

5.2 Mono pump

This pump will feed batter from storage tank to the aerating machine after filtering. It is Netzsch brand with inverter to control its speed.

5.3 Continuous aeration system 1set

Continuously aerating machine

Its capacity is up to 500kgs aerated marshmallow/hour

A. syrup comes from the buffer-tank to this mixer,then mix with fresh and compressed air from the aeration system. For avoiding the high temperature during the fast-speed mixing, there will be a cool water (5℃-20℃)from the water chiller

B. Driving of the mixing head: 50hz.the helical geared motors is with a special device of class sealed with the ip-55. power is 15 kw, 250 rpm,50 hz.

Continuously aeration system consists by following machine:

- Material transfer by mono pump which controlled by plc and inverter, digital displayed; aisi304 pump head, with s.s cover , height adjustable; direct driving gear box with 1.5kw motor; with single mechanical sealer;

- SS304 aerating head, rotor and stator with 17rows square needles, efficiency capacity 2l;mechanic seal;with drain water outlet; 15kw SEW gear box driving direct, with inverter control, outside and inside both cooled by chilling water.

- manual/automatic air dosing with flow meter

- PLC automatic controlling the air infeeding capacity.

- Outlet pressure control,sms38 outlet and inlet,back pressure valve with silicone cover and pressure control

- Output controlled by PLC.

- Main pump,mixing head controller and parameter displaying on

- The touch screen.

- 3-way pneumatic valve for feeding aerated batter to batter extruder drop drain is also controlled by the touch screen.

- All the parameter will displaying on the “Delta” touch screen.

- Which fixed on the machine,

- Graph type displaying touchable screen, can save difference recipe.

- Protecting standard: ip56

- Single layer s.s pipe with 40micro filter. Sms38 inlet and outlet .

- Dimensions:2150mm x 810mm x 400mm

- Cleaning pump is included.

- One set of filters are included.

- They will be delivered as a complete set.

Water chiller unit and with connecting piping and by-pass. 1SET

The chiller unit is a device that allow you to regulate the temperature into the mixing head, and extract the heating generated during the working phase. To cool the water during production from the pre-mixer /the buffer tank/the mixing head . This water chiller has its own tank and cooling circuit system.so no extra water consumption except the water which is needed through the internal .water temperature can be adjusted to be 5-20 degree celsius.

- Chilling capacity:5hp compressor

- Working pressure≤ 1.2mpa.

- Cooling type: air cooling

- Chilling water flow capacity: 20 l/min.

6.Color dosing & mixing system(4 colors)

Automatic add color, flavor, acid and fruit juice concentrate and mixing in the static agitator, ensure to get the best taste. All material is ss304, the pump use Germany sera pump.

- 4*piston pump 0~3L/H

- The color injection system consist of 4 buffer tank with level glass, 4injection pumps and the connecting pipe and 4static mixers all in jacket execution

- The level glass has a dual function, first it show s level of the buffer tank, and secondly the level glass can be used as calibration, by turning a valve, to check the capacity of the injection pump

- The buffer tank is fitted with a removable cover and sieve, in order to catch any contamination during filling, at the bottom of the tank a discharge valve is fitted

- In the inlet piping between the tank and pump, a filter is fitted

- 4 frequency inverter, to adjust the speed of the individual pump

- The piping after the pump is fitted with manually operated three way valve, so the system can be pressure free, with the second valve the operator can choose to calibrate the pump or inject into the system

- Pump ,buffer tank and all stainless steel pipe are installed on a stainless steel frame

- Buffer tank

- Material:316 stainless steel, with bottom drain valve

- Net volume:15L

- Outlet: 1/2” from bottom, to prevent un-dissolved powders getting into the pump

- Piston pump

- Drive:0.37kw geared motor

- Pump capacity:0~3L/H

- Connection suction side: 1/4” thread pipe connection

- Connection outlet side:1/4” thread pipe connection

- Capacity control: frequency converter adjustable

- Piping

- Before pump: 1/2” fitted with a strainer

- After pump: 1/4” stainless steel

- Valve: 2 manually operated three way valves

- Check valve: 2 check valve for backpressure control

- Execution: all pipe work 316 stainless steel 1/4”

- Static mixers

- After each pump: 1” stainless steel, jacketed

7.Pipes and fitting system will be designed according clients’ layout of factories. The pipes and fittings are not included in the quotation.

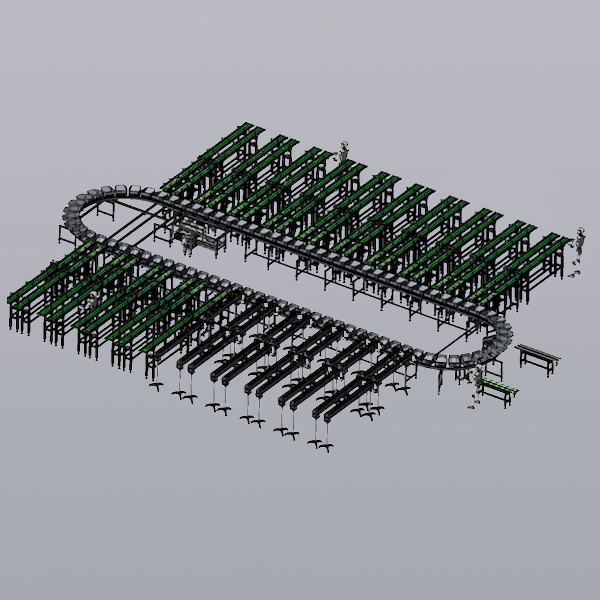

8. Marshmallow forming line

8.1Main conveyor

The system consist of a 1100mm wide conveyor,20 meters long. On this conveyor, there is a starch sprinkler to spread one layer of starch to prevent sticking of marshmallow to the blt. A forming roller will press channels in the starch ad the same distance as the nozzles in the manifold extruder.

The extruder is built shortly behind the duster and extrude marshmallow ropes on the channels of the starch layer. After extruding, there is another starch sprinkler will sprinkle one layer of starch to cover them. Then cutting and go to aging conveyors or dry rooms.

- Power: 1.5kw

- Speed of belt is adjustable.

- There is a mesh filter at the end of the extruding line.

Starch bottom sprinkler

- starch layer vibrating feeder

- starch buffer by hand

- starch layer thickness regulation

- support for fixation on the conveyor frame

- drive:0.37kw, frequency inverter control

- capacity:200kg/h

8.2 jacket manifold extruder

- Motor:1.5kw SEW

- size: L*W,1300*500

- capacity:500KG/h

- one separate into 16pcs

- depend on final product, to be offered separately.

- Die alu. Super hard material,jacket without water to keep warm.

- one separate into 15-17 and there are four rows for four colors of marshmallow.

- Motor:1.5kw SEW

- Die: alu. Super hard material, jacket without water to keep warm.

8.3 marshmallow conveyor

the system consist of a 1250-1300mm wide conveyor, 20m long, on this conveyor a starch duster produces a layer of starch to prevent sticking of the mallow to the belt, a forming roller will press channels in the starch at same distance as the nozzles in the manifold extruder

the extruder is built shortly behind the duster and produces mallow ropes into the channels of the starch layer. After extrusion the mallow ropes are covered by a thick layer of starch from the starch sprinkler. The cutting of the mallow into the correct product lengths is done by guillotine cutting through both the starch layer and the mallow. The cutter has adjustable cutting speeds to adjust the final product length based on strokes/min, and conveyor speed.

After cutting, at the end of the conveyor, the product drops into a cross conveyor /starch shaker to remove most of the excess starch and separate the mallow pieces, from this point it will be elevated and fed into a final cleaning drum for removing final starch of the product.

A starch dust collector system connect to the starch shakers, guillotine and starch cleaning drum, will filter most of the air-born starch from the areas where starch dust is created

mallow conveyor

- dirve:1.5kw SEW

- belt speed adjustable

- mallow conveyor 1270mm wide, 20m long

- wire scraper at the end of the conveyor to remove excess starch

- reinforcements for equipment to be fixed to the conveyor frame

8.4 starch top sprinkler

- starch bunker with outlet sieve

- starch layer thickness regulation

- support for fixation on the conveyor frame

- drive:0.37kw(SEW)

- capacity:350kg/h

8.5 guillotine

- under belt support

- stainless steel frame and support

- cutting speed adjustable up to 300strokes/min

- drive:1.8kw (YASAKAWA)

8.6 starch shaker

8.7. starch filter (shaker)

- starch shaker cross conveyor to separate starch and mallow pieces and transfer them to elevation conveyor

- perforated starch sieve

- AJAX shaker

- Connection to the starch return screw conveyor system

- Starch drain will be by dry room or other machines.

8.8 inclined conveyor

8.9 starch cleaning machine

- de-starch drum to remove starch prior to packing

- Elevating angle 45°

- De-starch drum in stainless steel execution

- Adjustable product retention time in de-starch drum

8.10 Inclined conveyor

8.11 Starch dust collection

- Collecting the starch of depositing machine and other related machines

- It is controlled in the electric cabinet of the depositing machine.

- Electric components: Schneider+Zhengtai

- Fan and silencer: Made in China

- Solenoid valve: Made in China

Specifications

Featured Products

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message