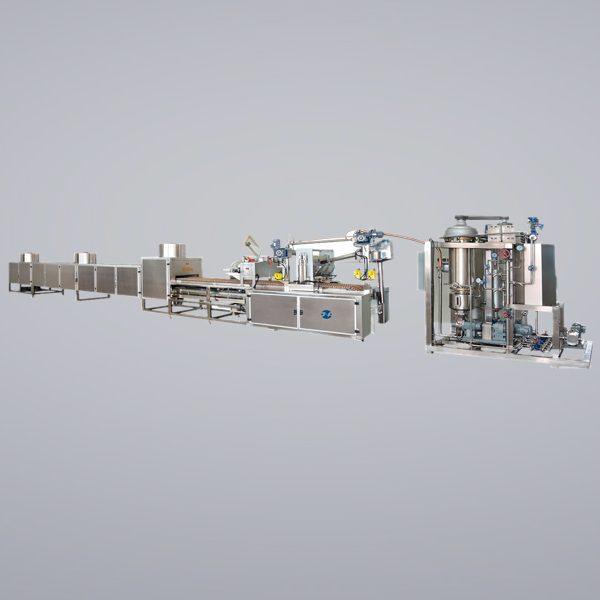

Jelly Candy Depositing Line Durable Gummy Candy Machines

D&R Machinery

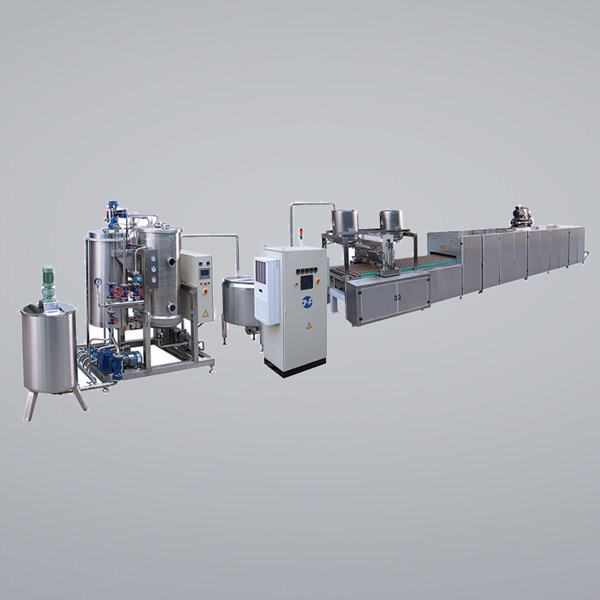

The DRSF-J series Vacuum cooker and jelly candy depositing lines are the advanced equipments for jelly candies with aluminum moulds. They are the best choice for producing carrageenan, gelatin solid and half solid candy.

Leave An Inquiry

Description

The BRT series vacuum cooker and soft candy depositing plant are the advanced equipement for soft candy with aluminum moulds. They combined by mechanical, electrical and pneumatic, and can be controlled by servo drivers. With tight construction and high automation, they are the best choice for produce carrageenan, gelatin solid and half solid candy.

Type: Jelly candy depositing machine is for making jelly candies. Combined with mechanical, electric and pneumatic.

Structure: Full machine driven by servo motors, controlled by 5 axels motion controller. We have one row of moulds, two rows of moulds, three rows of moulds and four rows of moulds jelly candy depositing machine. With tight construction and high automation.

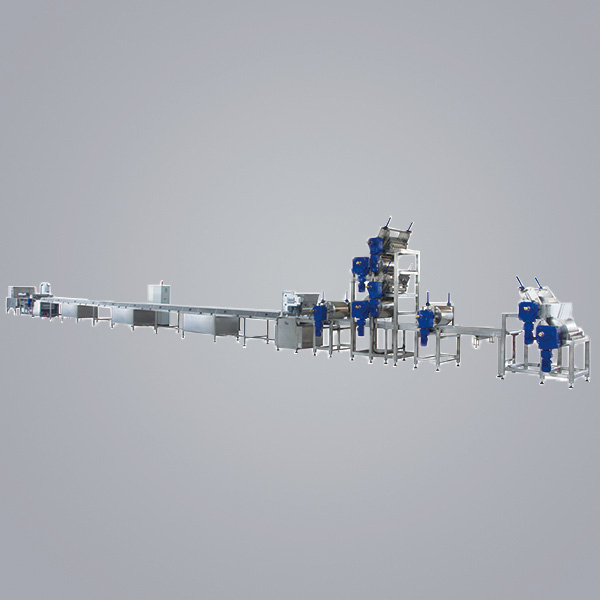

The process of pectin jelly candy depositing line:

- Pectin dissovling pot

- Sugar dissolving pot

- Storage tank

- Jelly candy depositing machine with cooling tunnel

- Conveyor

- Sugar/oil coating machine

- Layers cooling tunnel

|

1. |

Dissolving pot |

Jacket and 200L |

|

2. |

Gear pump |

The part which touch syrup is ss304. 1″ |

|

3. |

Pectin melting tank |

260L, jacket with agitator |

|

4. |

Storage tank |

Jacket,heated by hot water |

|

5. |

Vacuum cooker |

Siemens PLC and touch screen(max.400kgs,Schneider brand of electric components, spiraxsarco brand of steam control system, stainless steel rotary pump) |

|

6. |

Depositing line |

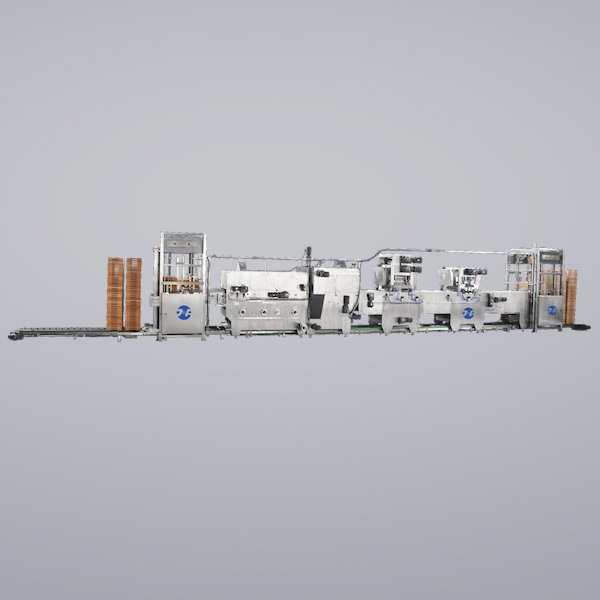

Depositing unit (304 stainless steel shell) ( it can produce one color candies, two colors,center-filling gummy candies), the touch screen is Siemens brand, Schneider electric components, Yaskawa servo motors and Parker drivers. two colors two flavor hoppers, three flavor pumps,the total length is 13m. pneumatic demoulding and cover is ss304.There is an oil sprayer.One 10HP Chiller |

|

7. |

Candy mould |

According client’s requirement |

|

8. |

Declined conveyor |

SS304 frame |

|

9. |

Sugar coating machine |

The parts which touch with machine is ss304 |

|

10. |

Declined conveyor |

SS304 frame |

|

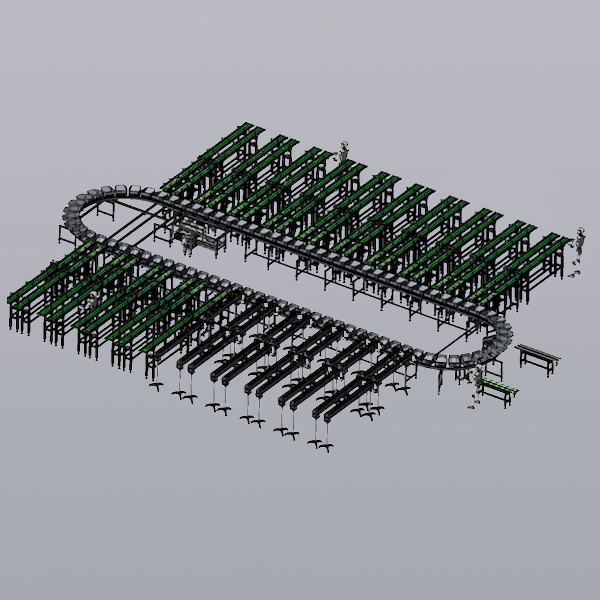

11. |

Seven layer cooling tunnel |

SS304 frame,15HP chiller |

Specifications

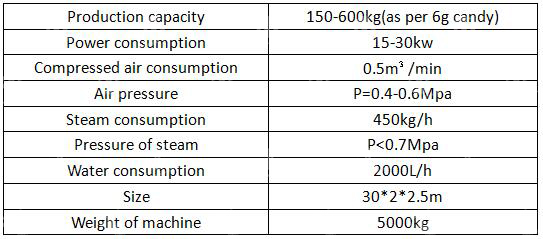

| Capacity | 150~600 Kg/h |

| Steam Consumption | 450kg/h |

| Steam pressure | 0.4~0.8Mpa |

| Temperature of workshop | 20-25℃ |

| Dimension(L*W*H) | 35000*2300*3100mm |

| Power Consumption | 15-30kw |

| Weight of candy | 3.5-15g |

| Compressed air consumption | 0.6m³/min |

| Humidity of workshop | 55% |

| Weight | 6000 kg |

Featured Products

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message