DR-QMJ1000 Chocolate Ball Mill Machine

D&R Machinery

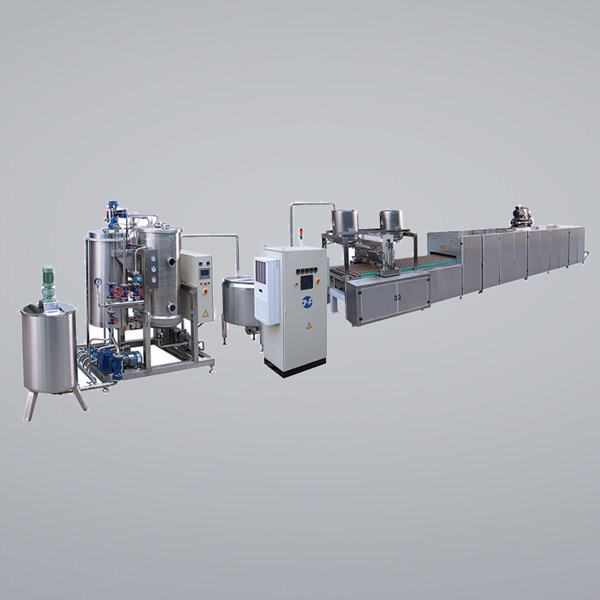

It is a standard and individual ball mill machine for continuously grinding chocolate.

Leave An Inquiry

Description

- Main motor: Siemens or ABB, Delta/Honeywell frequency converter, Other electrics: Schneider PLC, Omron etc.

- 220V/60HZ/3Phase.

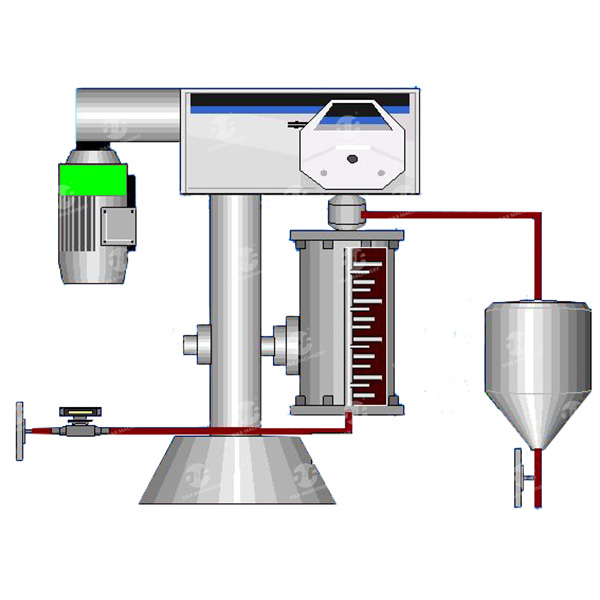

- With one main machine, one cool-hot water ex-changer, one mid-tank with magnetic filter and one control system.

- The mid tank with magnetic filter is fixed with American Banner ultrasonic sensor.

- The machine needs 6~8℃ cooling water when working. Customer prepares water cooling unit to supply cold water for ball mill.

- The standard diameter of steel balls is 10mm when machine leaves factory, we also can use 8mm, 12mm balls according to requirements.

- Firstly grinding material in conch or premixer 3~4hours(fineness 75~80micron---to ball mill---to holding tank

Technical Parameter

|

Model |

DR-QMJ1000 |

|

Main motor power(kw) |

55 |

|

Capacity(kg/hour) |

1000 |

|

Electrical heating power(kw) |

9 |

|

Balls quantity(kg) |

1000 |

|

Steel Ball Size |

6.3mm |

|

Grinding fineness(micron) |

18~25 |

|

Weight of machine(kg) |

4900 |

|

Outside dimensions(mm) |

100*2000*3100 |

|

Electrics Power |

220V, 60Hz, 3phase |

Advantages

- Individually & Continuously working: It is a standard and individual ball mill machine for continuously grinding chocolate, no need add any extra buffer tank for recycle batch grinding to satisfy the required fitness of chocolate, it is the big difference compare to normal ball mill in market.

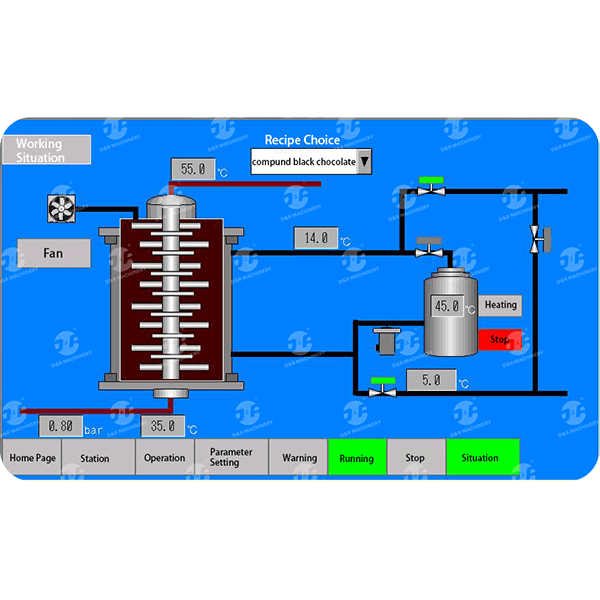

- PLC Online Commissioning system: In order to avoid the problem of not being able to provide on-site service due to the epidemic situation, we have added PLC remote assistance function in the equipment system, so that our engineers can link the equipment online to help debug the equipment.

- Strong magnetic filtration system for safety: A strong magnetic filtration system is installed at the outlet of the system to filter chocolate slurry to ensure food safety.

- High quality materials and fine workmanship for machine stable running: During the outbreak, the stability and safety of the equipment is what we have been committed to.

- Accurate detection and control of temperature: We are equipped with advanced temperature sensors to detect the temperature of chocolate paste when the equipment is working. We can adjust the temperature to ensure the best quality of chocolate paste

- Dynamic simulation on touch screen: The internal operation and data of the equipment are displayed on the touch screen in real time, which is convenient to observe the operation of the equipment and adjust the parameters

Specifications

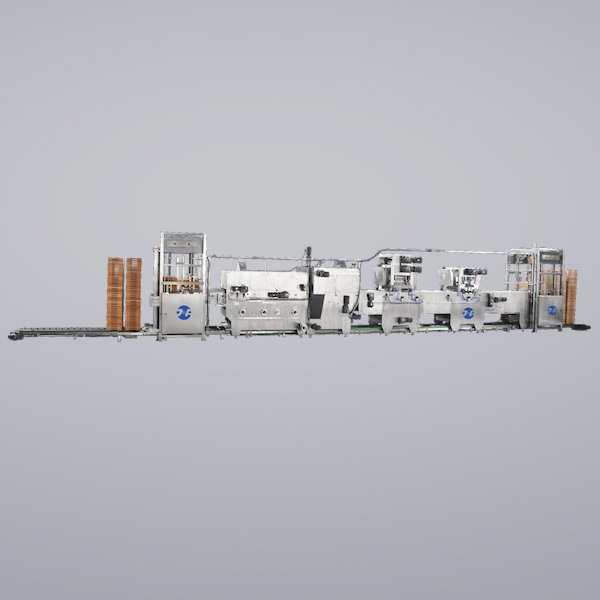

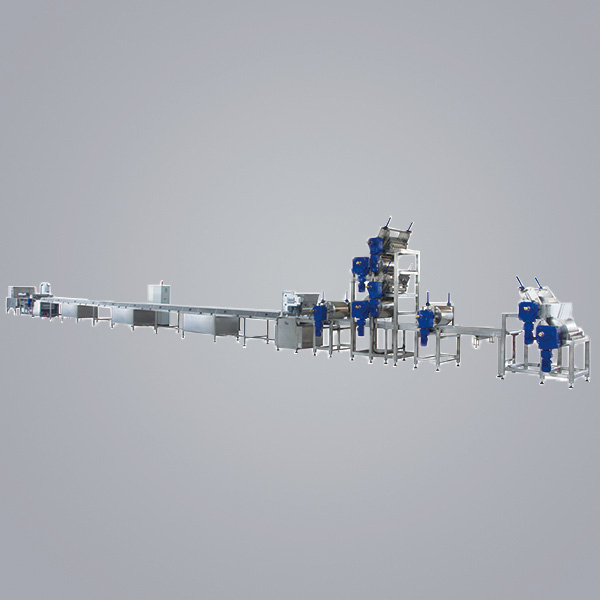

Featured Products

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message