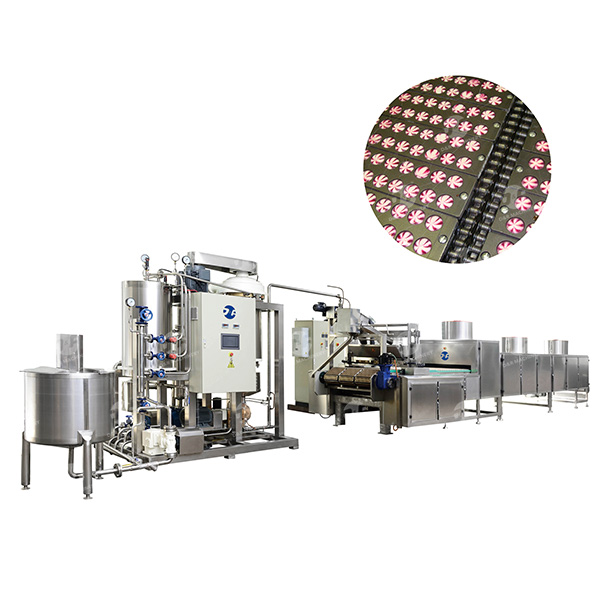

Servo Driven Hard Candy Depositing Line

D&R Machinery

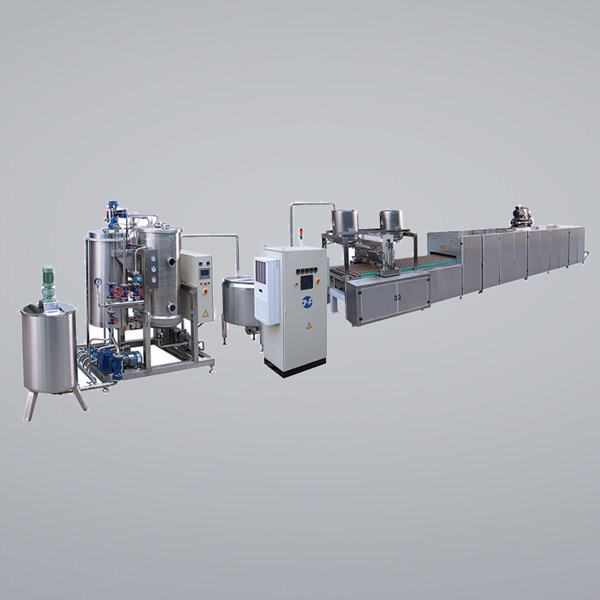

The DRSF series microfilm cooker and servo driven hard candy depositing lines are the advanced equipment for producing hard candies, they are driven by servo motors and controlled by motion controller.

They can produce transparent candy, center-filled candy, two colors&two flavour candy, striped candy, etc.

Leave An Inquiry

Description

The DRSF series microfilm cooker and servo driven hard candy depositing lines are the advanced equipment for producing hard candies, they are driven by servo motors and controlled by motion controller.

They are driven by servo motors and controller by intelligent card, with tight construction and high automation and also with large outputs.

They can produce transparent candy, center-filled candy, two colors&two flavour candy, striped candy, and butter scotch, etc.

PURPOSE AND CHARACTERISTIC

The DRSF series microfilm cooker and servo driven hard candy depositing plant are the advanced equipment for candy depositing,they are driven by servo motors and controlled by intelligent card,with tight construction and high automation and also with large outputs.They can produce transparent candy,center-filled candy,twin color & twin flavour candy,stripe candy and butter scotch,etc.

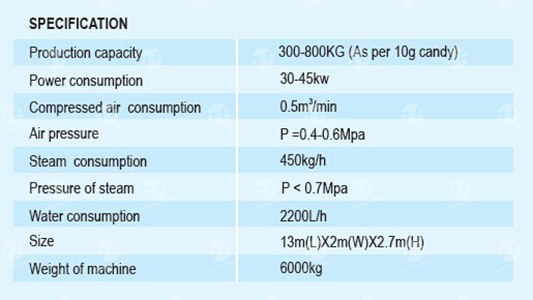

SPECIFICATION

Production capacity 300-800KG(As per 10g candy)

Power consumption 30-45kw

Compressed air consumption 0.5m3/min

Air pressure P=0.4-0.6mpa

Steam consumption 450kg/h

Pressure of steam p<0.7Mpa

Water consumption 2200L/h

Size 13m(L)X2m(W)X2.7m(H)

Weight of machine 6000kg

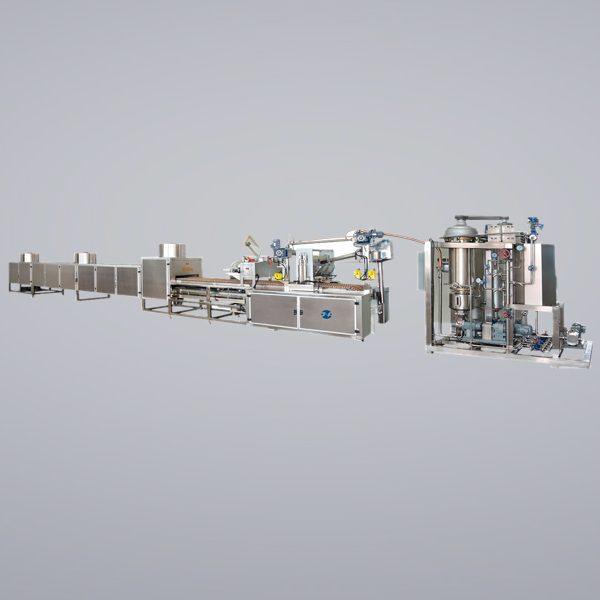

PURPOSE AND CHARACTERISTIC

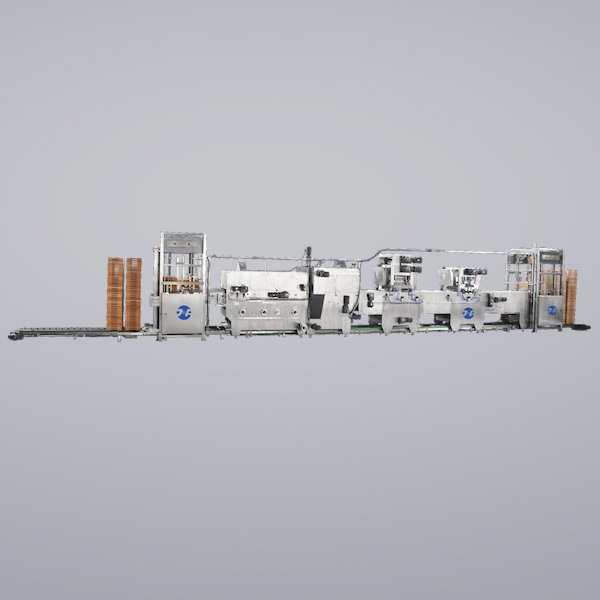

BLJC series vacuum microfilm cooking continuous pour shaping auto-producing line is the advanced confectionery machine at the present time,it gathers machine and electric all in one.This machine have output and good production efficiency.It can produce not only crystal candy,strip candy and coffee candy.The produced candy which made from this machine have excellent clarity with a high quality appearance surface and smoother moth feel.

SPECIFICATION

Production capacity 300-800KG(As per 10g candy)

Power consumption 30-45kw

Compressed air consumption 0.5m3/min

Air pressure P-0.4-0.6Mpa

Steam consumption 450kg/h

Pressure of steam P<0.7Mpa

Water consumption 2200L/h

Size 13m(L)X2m(W)X2.7m(H)

Weight of machine 6000kg

PURPOSE AND CHARACTERISTIC

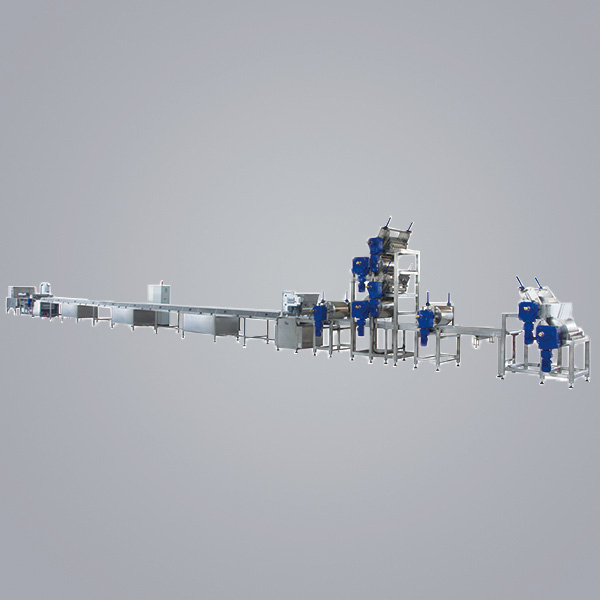

D&R hard candy forming line AUTO-WEIGHING DISSOLVING SYSTEM,MICROFILM COOKER OR MICROFILM ROTARY COOKER,COOLING TABLE,BATCH ROLLER,ROPE SIZER,FORMING MACHINE AND COOLING TUNNEL.Machine with high automation,higher output,good looking of candies,suit for producing transparent candy,fruit candy,jam filled candy,power filled candy,power filled candy and so on.

SPECIFICATION

Main parts Capacity(kg/h) Power(kw) Dimension(mm)

Jam pumo 30L/h 1.95 700*500*1180

Heat-proof roller-stand Batch roller 6.85 2490*660*1920

Stripe pulling device Rope sizer 3.42 1420*580*1890

Molding machine Hard candy<500kg/h 4 2420*10880*1385

Crumb collector Flow velocity 1800-3700m3/h 2.2 1300*1200*2200

Cooling cabinet Cooling time 5-7.5min 30 11800*1980*1980

PURPOSE AND CHARACTERISTIC

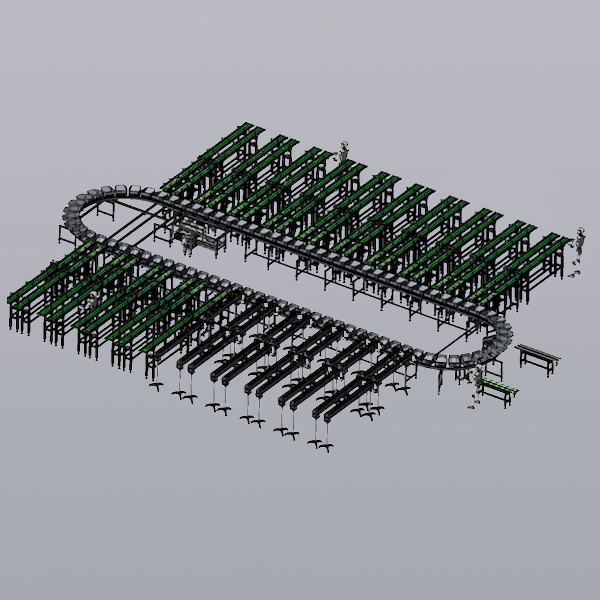

Model BZBA microfilm cooker has the function of auto-continuous sugar-cooking and auto-control the temperature.High output,good quality of sugar cooking .high transparence of syrup and convenient operation,It can be used together with BLJC depositing machine or BCBT lollipop production line.It is the perfect equipment of sugar-cooking

SPECIFICATION

Capacity 300-500KG(AS PER 5G CANDY)

Electric consumption 16kw

Compressed air consumption 0.3m3/min

Air pressure p=0.4-0.6Mpa

Steam pressure 450kg/h

Steam pressure p<0.7Mpa

Water consumption 2200L/h

Size 2.3m(L)*2M(W)*2.7m(H)

Machine weight 2500kg

PURPOSE AND CHARACTERISTIC

BDZA microfilm rotary cooker controlled by PLC and touchable screen

This machine have a large capacity,cooked high quality slutty,cryoconcentration during vacuuming,it is the best machine for cooking high cream and high milk contents candy,fresh juice candy,toffee and so on.

SPECIFICATION

Production capacity 300-500KG

Power consumption 25kw

Compressed air consumption 0.3m3/min

Air pressure P-0.4-0.6Mpa

Steam consumption 400kg/h

Pressure of steam P<0.3Mpa

Water consumption 3000L/h

Size 3.0m(L)X1.8m(W)X3.6m(H)

Weight of machine 3600kg

PURPOSE AND CHARACTERISTIC

Specification AFD-11 AFD-12

Capacity(KG/H) 600-750 1200-1500

Power(KVA) 14.7 17.7

Compress Air 400 500

Steam Consumption 100 200

Steam Pressure 8 8

Mixing Tank 280 280

Dissolving Tank 320 320+320

Liquid Valve specification and quantity according the requirement of customer’s

Length * Width * High (mm) 2100*1400*3060 2100*1800*3060

N.W 1000 1300

Specifications

Featured Products

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message