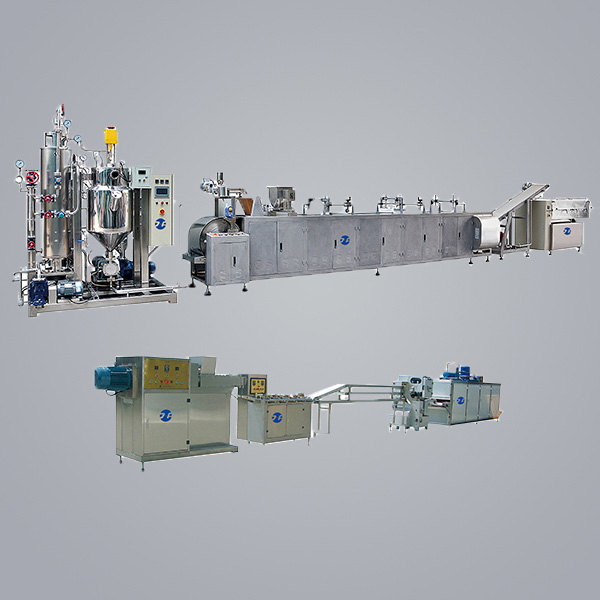

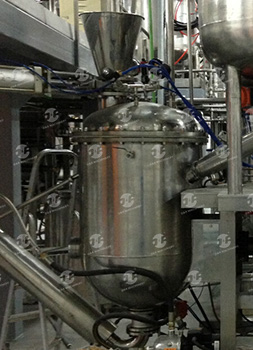

Elegant Production Line

D&R Machinery

Elegant candy production line from D&R machnery, the leading confectionery equipment manufacturer from China.

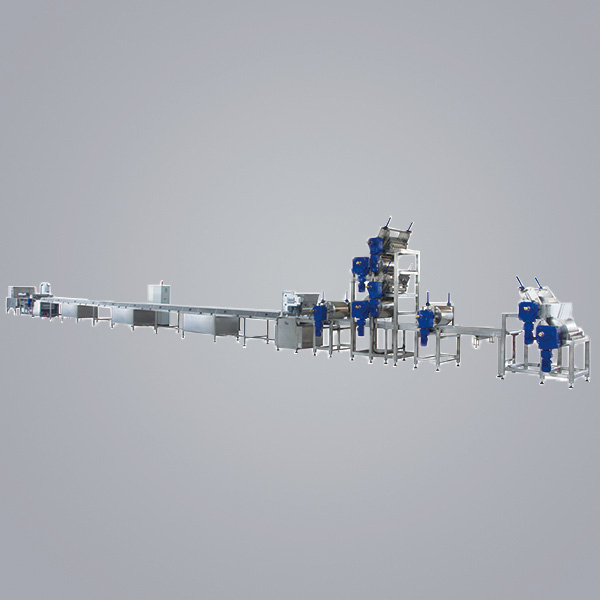

Leave An Inquiry

Description

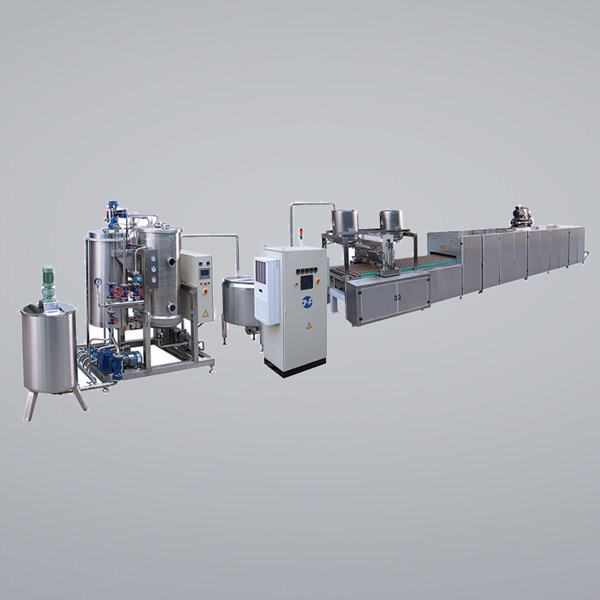

1. Automatic weighing and dissolving tank+coil vacuum cooker with aerator

1.1 Automatic weighing and dissolving tank.

1.2 Vacuum cookers and aerator

Batch cooker (2 units)

3.2.1 Volume:300L

3.2.2 SS304

3.2.3 Rated pressure:0.6 Mpa.

3.2.4 Motor of mixer:2.2kw

3.2.5 Mixing speed:37.5npm

3.2.6 There are the certificates for pressure containers

3.3 Aerate cooker(1 unit)

3.3.1 Mixing speed:0-14-npm (Danfoss inverter control speed)

3.3.2 Mixing motor:15kw

3.3.3 Volume:300L

3.3.4 Rated pressure:0.3 Mpa

3.3.5 Material:SS304,Jacket and keeping warm by hot water

3.3.6 Sealing: Mechanical sealing

Main parameter:

Production capacity: 300-600kgs/hour

Steam consumption: 300kgs/hour

Steam pressure: 0.6 Mpa

Power Voltage: 380V

Total power: 20KW

Compressed air consumption:0.3cbm/mintue

Compressed air pressure: 0.6 Mpa

Water consumption: 0.3cbm/hour

Electric cabinet:

- Isolated electric cabinet.

- PLC is MITSUBISHI brand

- Electric components: Schneider Brand

- aviation plugs to connect the wires of machine with electric cabinet.

Vacuum Parts:

- Vacuum pump: SK1.5(Chinese brand). Power:4KW.Speed:2800N/MIN

- SS304

Pneumatic Parts:

- Pneumatic solenoid valves: Festo

- Pneumatic angle valve: SXPC(Chinese brand)

- Pneumatic ball valve: Shanghai Huazhu

Frame:

- Frame is ss202(satin finish surface)

- Cover of the machine is SS202(satin finish surface)

- Syrup pipes are jacket and kept warm by hot water

02 Siemens PLC and touch screen

- The brands of valves,drain valves and Angle seat valves are Chinese.

- Siemens inverters

- Omron brand of temperature controllers

- The brand of electric components is Schneider

- Main motors are Chinese brands

- Pneumatic components are Airtac brand

- Total power:20.4kw

- Ss202 steel frame. The parts which contact products are ss304

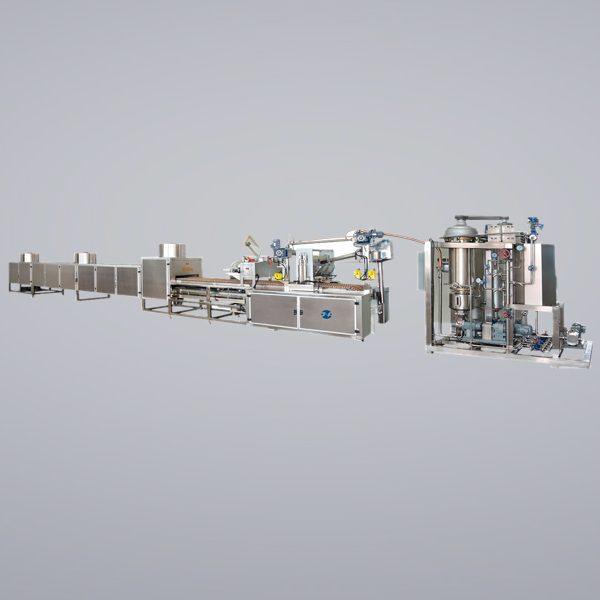

2. Cooling drum 1set

Jacket and chilling water in the jacket.SS304 outer layer and and mild steel with paint for the inner layer.

3. Pulling machine 1set

Specification:

- Style no.:DRLB-800

- Capacity: 500-800kgs/hour

- Shaft:12pcs

- Shaft rotational speed: 5-30rpm

- Motor power: 7.5kw

- Machine size: 2580X980X1830MM

- Machine weight: about 2800kgs

4. Jam pump(2sets)

Capacity at 100kgs/H(Max) , inverter controls the speed.

5. Extruder(2sets)

- Screws number 4 pcs

- Screw diameter 96mm

- Motor power 11kw

- Box heat power 1.8kw

- heat power 3kw

- Dimension 2130*1485*1824mm

- Speed 23.7r/min

6. Rope sizer(2sets)

It is warm keeping with over weight stopping system. 5sets wheels,1set for inlet and 4sets for adjusting the size.

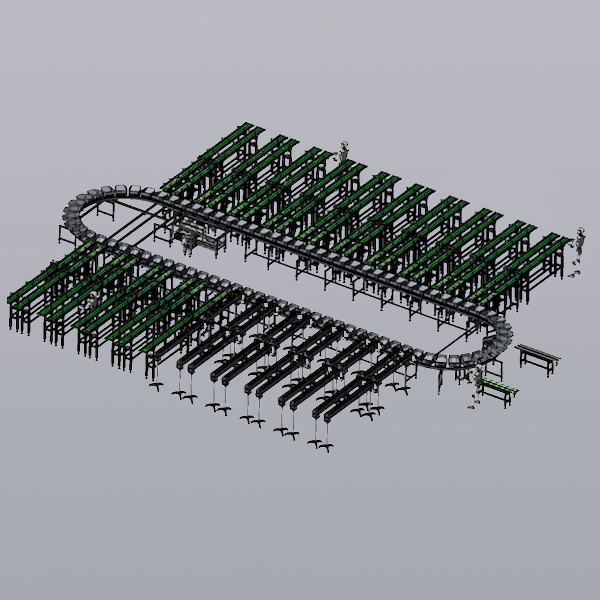

7. Three layers cooling tunnel(2sets)

Length 4m , with 220mm width. Inverter controlling the speed.

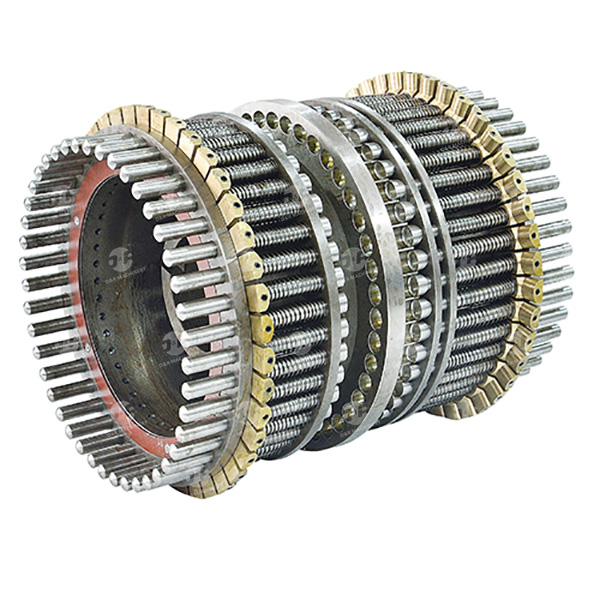

7.Chain die forming machine(2sets)

With heating system. Capacity at 300-500kgs/hour. as per the candy weight, with inverter control the speed. With 1 set die.

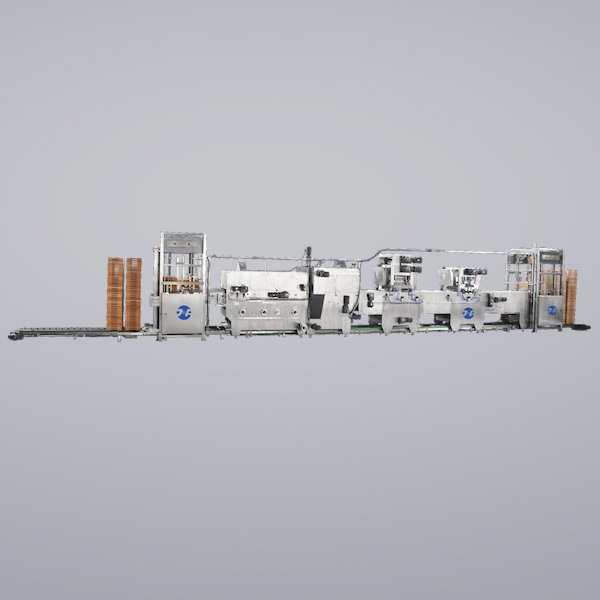

8.Swing conveyor and cooling tunnel

For spreading the candies into cooling tunnel equally. Power: 0.55kw

3 layers, automatic controlling the temperature of the cooling, with 7.5kw Chiller. Machine size : 6500 x1200x1800mm

Configuration:

- Low voltage electrical element: SCHNEIDER

- Inverter: BOSCH

- Chilling system: COPELAND

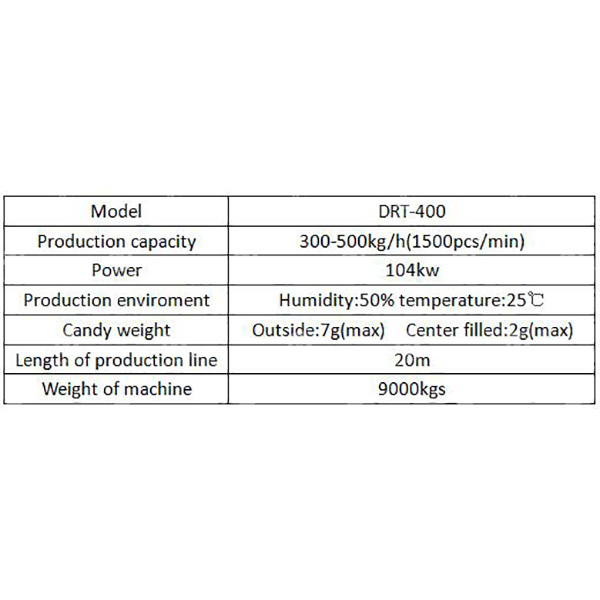

Specifications

Featured Products

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message