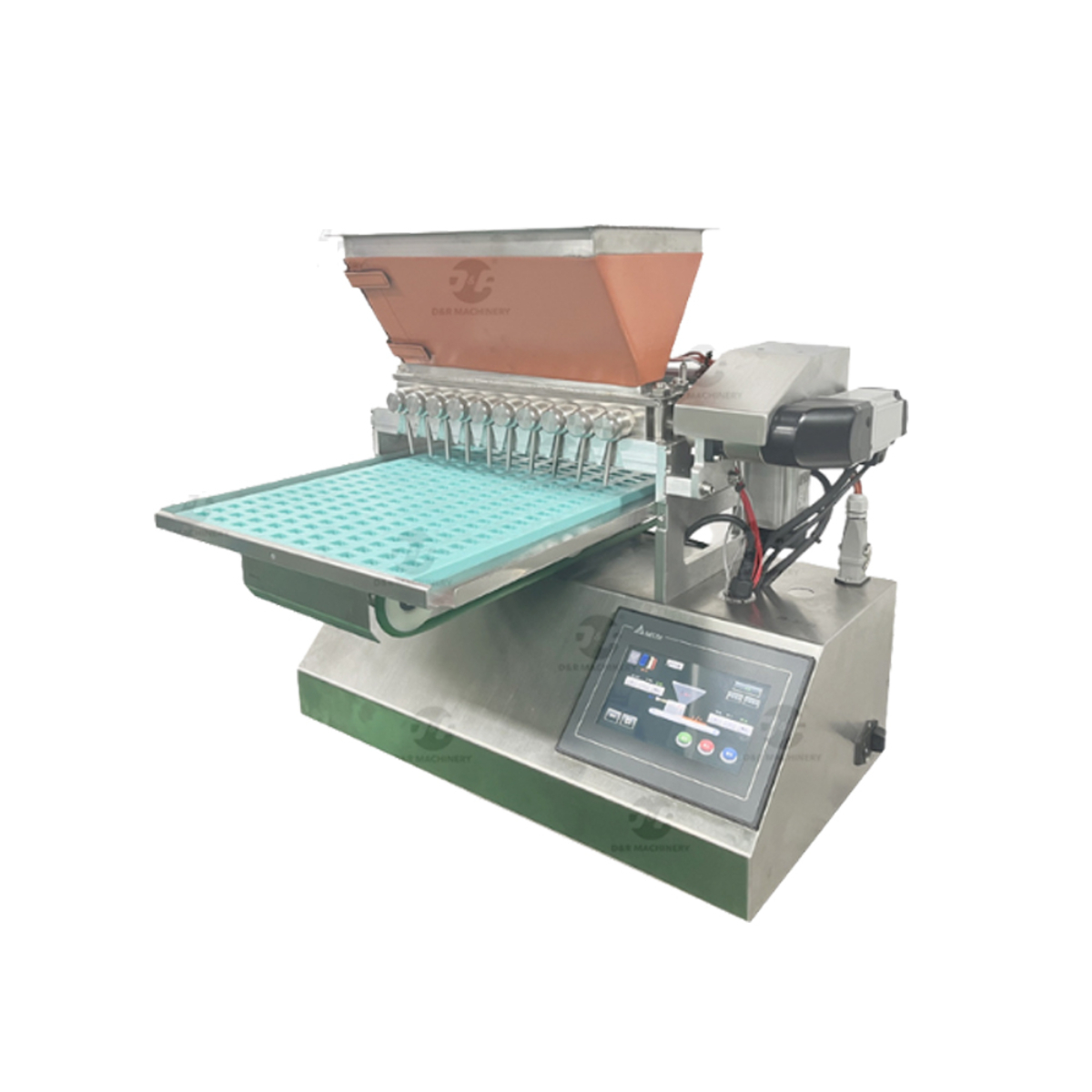

Table Top Depositor

D&R Machinery

Nicely priced table-top confectionery depositor is suitable for chocolate, caramel, jelly, hard candy soft candy and many more similar syrup depositing. The adjustable nozzles make it suitable for molds with different layouts.

Leave An Inquiry

Description

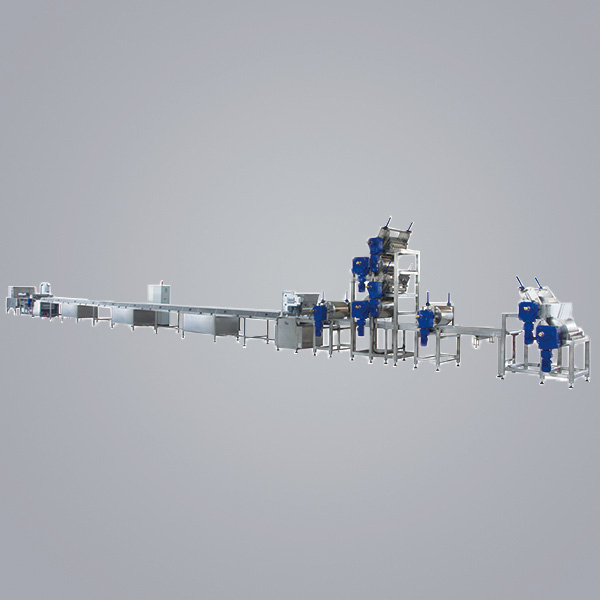

10 Holes Table Top Depositor

Nicely priced table-top confectionery depositor is suitable for chocolate, caramel, jelly, hard candy, soft candy and many more similar syrup depositing. The adjustable nozzles make it suitable for molds with different layouts.

Feature:

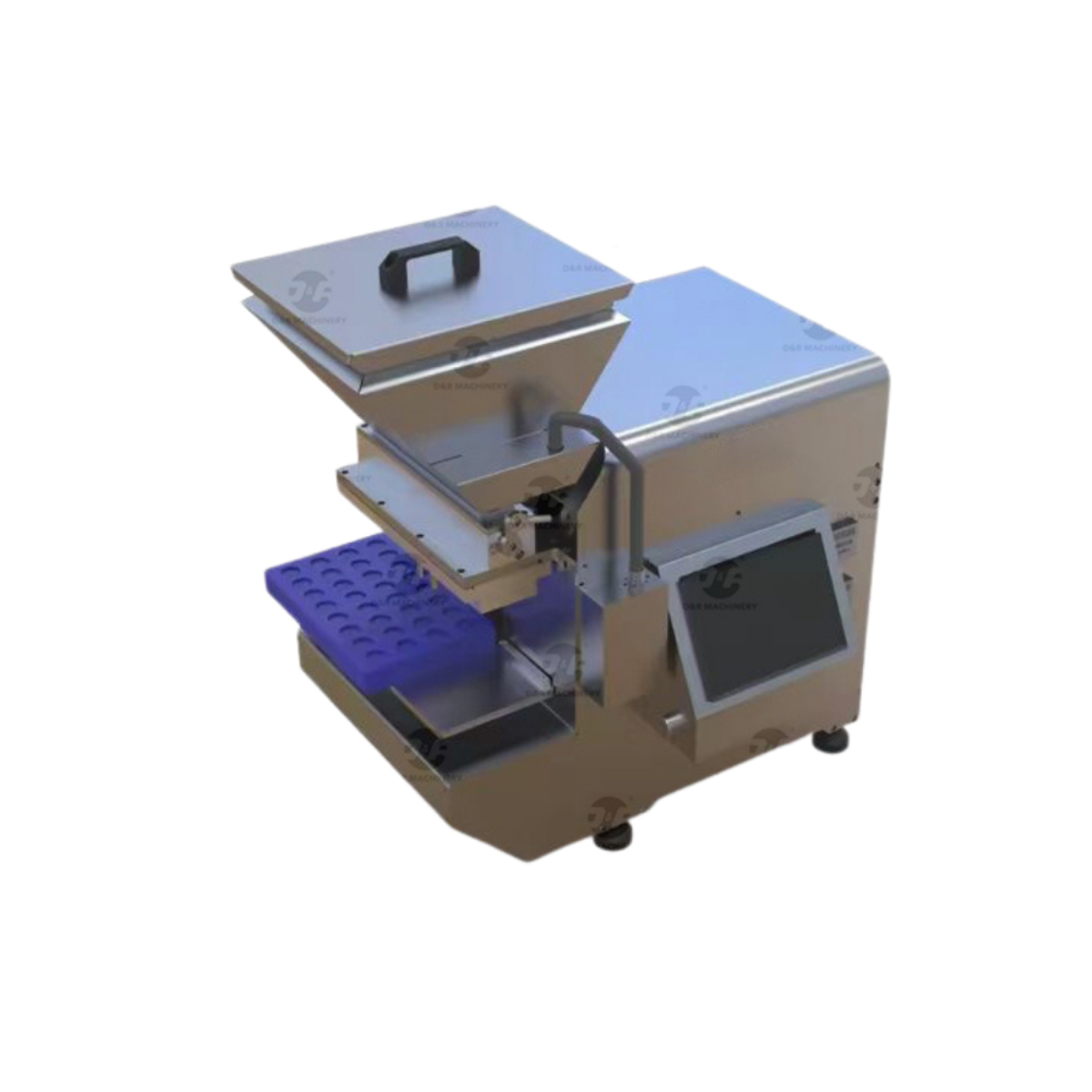

1. This depositor adopts a compact and space saving table top design

2. 10 adjustable and removable nozzles

3. 2 Servo motors+PLC controlled depositing with HMI

4. Double heating systems for hopper and nozzles

5. One mold holding tray for silicone and other soft molds

6. Suitable for chocolate, caramel, jelly, hard candy, soft candy and many more similar syrup

Compatible Equipment:

| Manual Demoulder | Air Press Demoulder | Mold Tray |

|

|

|

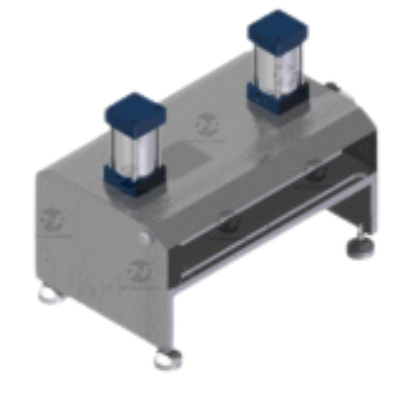

| *Hand-press demoulder is made of SSS304 and aluminium.

*It usually works with soft silicone moulds. *It can be customized according to different mould and candy size *The operation is simple and convenient. |

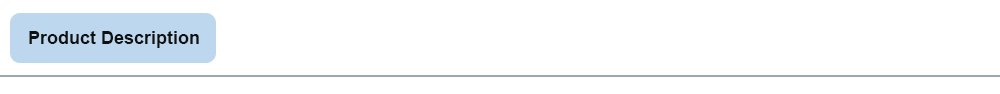

*Air-cylinder Press Demoulder is equiped with 2

strong air cylinder for pressing *It usually works with soft and hard silicone moulds. *It can be customized according to different mould and candy size *The operation is simple and convenient. |

*Customized size for different silicone mould.

*Made of SSS304 *Max width is 410mm. *By using a tray to hold silicone molds, the depositing process can be more stable and convenient. |

Depositor Details:

|

1. PLC Control with touch screen |

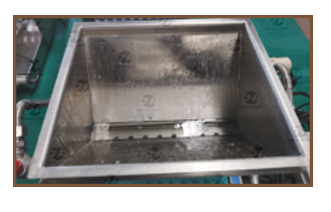

2. 10 Liters hopper |

|

3. Depositing nozzles |

4. Pistons |

TOTAL SOLUTION ,TOTAL CARE

TOTAL SOLUTION ,TOTAL CARE

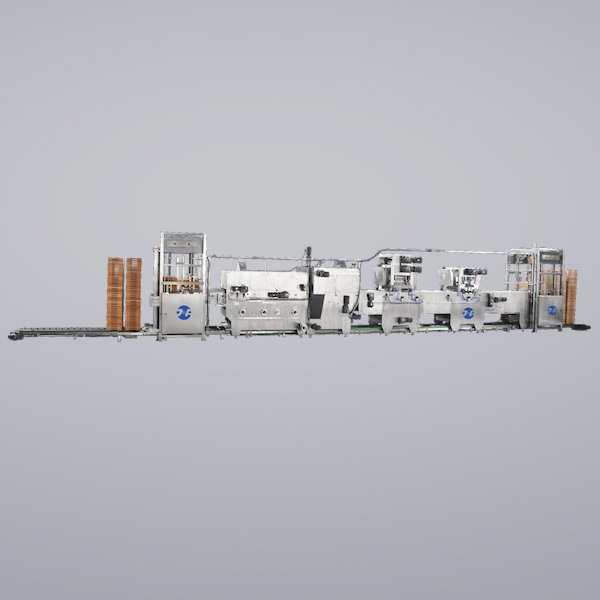

D&R Machinery are professional confectionery machine manufacturers with over 20 years in the business operating at the highest industry standards.

We've built a reputation on engineering, designing and delivering high performance total-solution confectionery machinery to clients with absolute precision around the world.

The confectionery machinery industry is a small world, and we've slowly become leaders in innovation and creative solutions for clients from all walks of the industry. D&R Machinery has become synonymous with one word and one world only in the confectionery machinery world and that is 'total-solution', that is end to to end turn key production of the highest quality confectionery machinery in the world.

Becoming the D&R Machinery you see today starts and ends with the word 'care'. You don't become the best without a plan that ensures our clients achieve the success they desire, and at D&R Machinery it starts with care and ends with trust, reliability and innovation.

D&R Advantages

* Technical advantages, industry-leading technical team, founding team of Chinese starch mogul and young generation of highly educated bilingual engineers.

* Modern service concept, provide customers with laboratory services for formula R&D, product & market analysis and planning, and control the risk before the product is put on the market.

* Rich industry experience, fully communicate with customers in the pre-sales service at the initial stage of the scheme, and customize the best scheme suitable for customers in combination with rich experience in international plant construction.

* For fine manufacturing, international famous brand spare parts are selected, and high-quality suppliers are selected by using the global spare parts. The purchased machined parts shall be subject to two inspections: delivery and warehousing, and shall be marked and warehoused after passing the inspection.

* The whole process of nanny service, we always keeps close communication with customers in the whole project service before, during and after sales, and provides professional suggestions for relevant supporting facilities from the overall perspective of the project.

1.D&R Machinery With Many Years Experience

2.High Technology team

3.Giving The Whole Project Solution

4. Consulting For Candies, Gummy, Chocolate And Its Packing

5.Always Giving The Economic Machine

6.Better Quality, Better Service After Sales For All Of The Customer

1.Q:Where are your company?

A:The company is located at F12, Shanshan Plaza, Yinzhou District, Ningbo, China.

2.Q:Are you direct factory?

A:We are both manufacturer and technical trading company. We are professional confectionery machine manufacturers with over 20 years in the business operating at the highest industry standards. We've built a reputation on engineering, designing and delivering high-performance total-solution confectionery machinery to clients with absolute precision around the world. Certainly,we welcome you to come visit our factory.

3.Q:What are your main products?

A:All kinds of Chocolate making machines, Candy making machines,Swiss roll and layer cake production line, Cadny bar production line and Packing machines.

4.Q:Do you have gurantee for your product?

A:We have a full quality control system.Every hardware part must be checked by the quality inspector before the products enter to the warehouse.Our electric elements are all famous brands, most of them are imported. When each machine is finished, we will invite customers to test and run the machine in our factory to ensure the high quality of our machines. Besides, we have CE, and SGS certification.

5.Q:What is the heating temperature of the depositor?

A:Maximum temperature is 130 degrees.

6.Q:What is the spacing distance of pouring nozzle?

A:35mm, and each nozzle can be adjustable&removable.

7.Q:What products are this depositor suitable for?

A:Chocolate, gummies, jelly, hard candy etc.

8.Q:What's molds does this depositor use?

A:PC molds, silicone molds, and the width of mold should not exceed 410mm.

9.Q:How to clean the depositor?

A:Remove necessary parts and clean by hot water.

10.Q:How can we contact you?

A:Here is contact information:

Contact company: Ningbo D & R Machinery Co., Ltd

Direction phone:+86 574 88304275

Fax:+86-574 87839559

Website: https://dr-machinery.com http://sweetmachinery.com

Specifications

| Candy Type | Hard Candy,Gummy Candy,Chocolate... |

| Transport Package | Wooden Case |

| HS Code | 843830000 |

| Material | SS304 |

| Capacity | 2-4molds/Min, 60-100kg/H |

| Weight | 90 Kg |

| Power | 2.2 Kw |

| Function | High Output |

| Dimension | 80*60*70cm |

Featured Products

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message