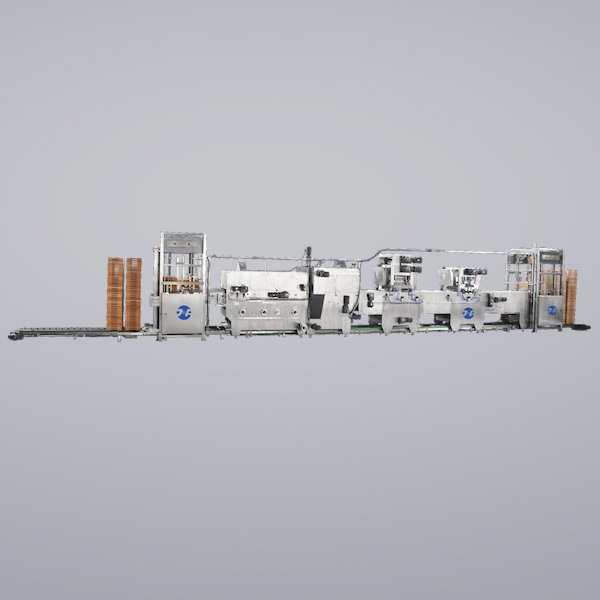

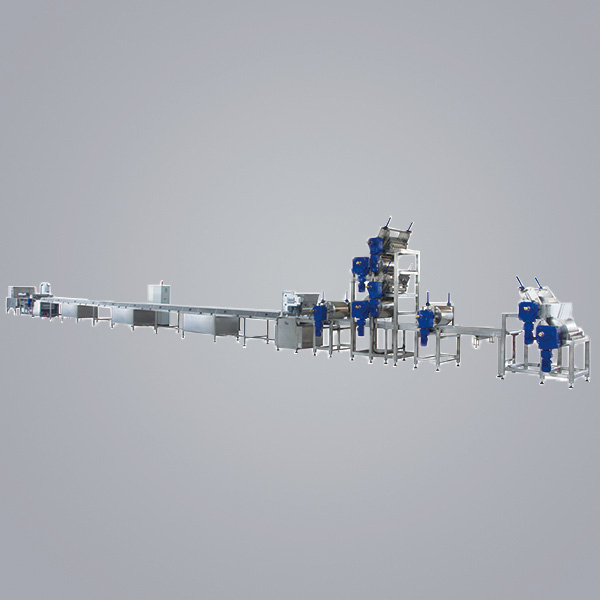

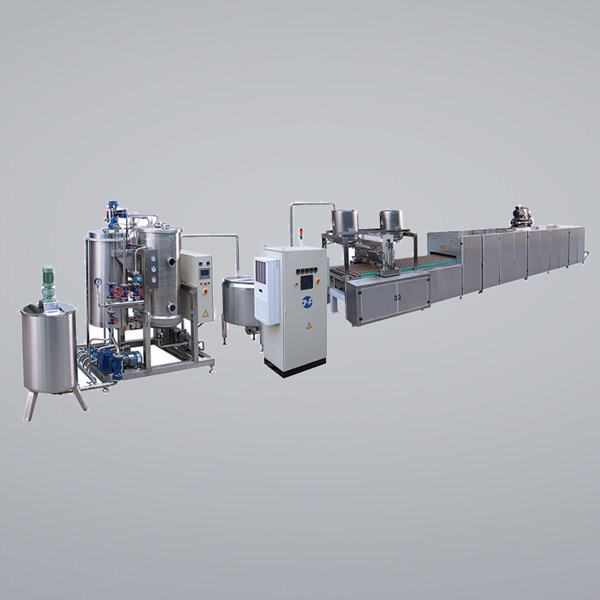

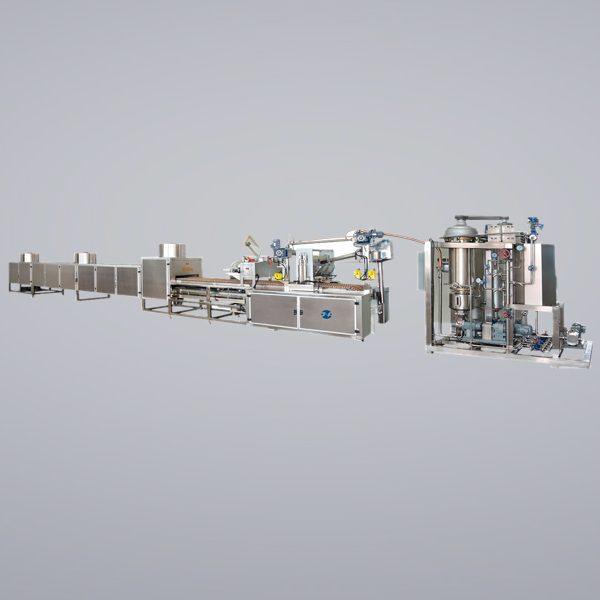

LAYER CAKE/ SWISS ROLL PLANT

D&R Machinery

The products made by our machine allow you to achieve a

better texture, a highly improved mouth-feeling sensation,

less calories and cost savings. We offer you the opportunity

through our technology and our food technologists to improve

and develop your products.

Leave An Inquiry

Description

PURPOSE AND CHARACTERISTIC

The products made by our machine allow you to achieve a better texture, a highly improved mouth-feeling sensation, less calories and cost savings. We offer you the opportunity through our technology and our food technologists to improve and develop your products. The entire production line with food sanitary standard, and there is no hand touch on the products till the end of packing.

|

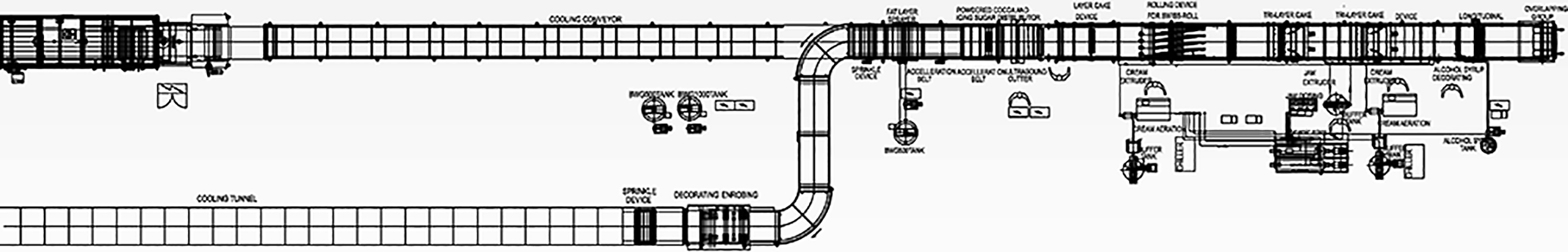

1. Pre-mixer for sponge cake |

11. Longitudinal cutter |

21. Curve 180°C conveyor |

|

2. Buffer tank with agitator and double jacket |

12. Syrup dosing unit |

22. Enrober |

|

3. Continuous batter aeration machine with mono pump for sponge cake |

13. Jam/cream extruder |

23. Cooling tunnel |

|

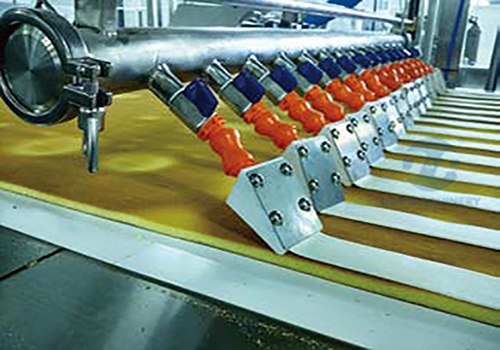

4. Automatic band oiler |

14. Pre-mixer of cream forsponge cake |

24. Decorating machine |

|

5. Sponge depositor |

15. Buffer tank with mono pump for cream/jam |

25. The 2nd cooling tunnel |

|

6. Tunnel oven |

16. Continue cream aeration machine |

26. Automatic packing line |

|

7. Gas burner |

17. Two layer forming device |

|

|

8. Transit conveyor |

18. Pressing roller |

|

|

9. Conveyor for cooling |

19. swiss roll/mini roll forming device |

|

|

10. Complete working bench |

20. Ultrasonic cutters |

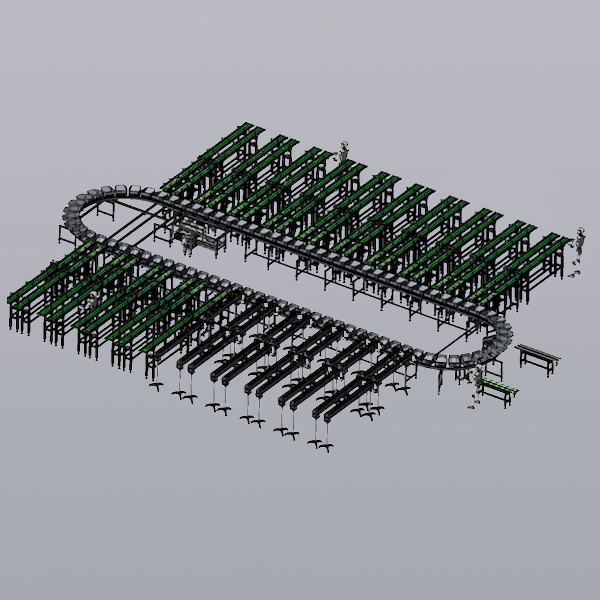

PRODUCTION LINE FLOW CHART OF LAYER CAKE AND SWISS ROLL

Specifications

Featured Products

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message