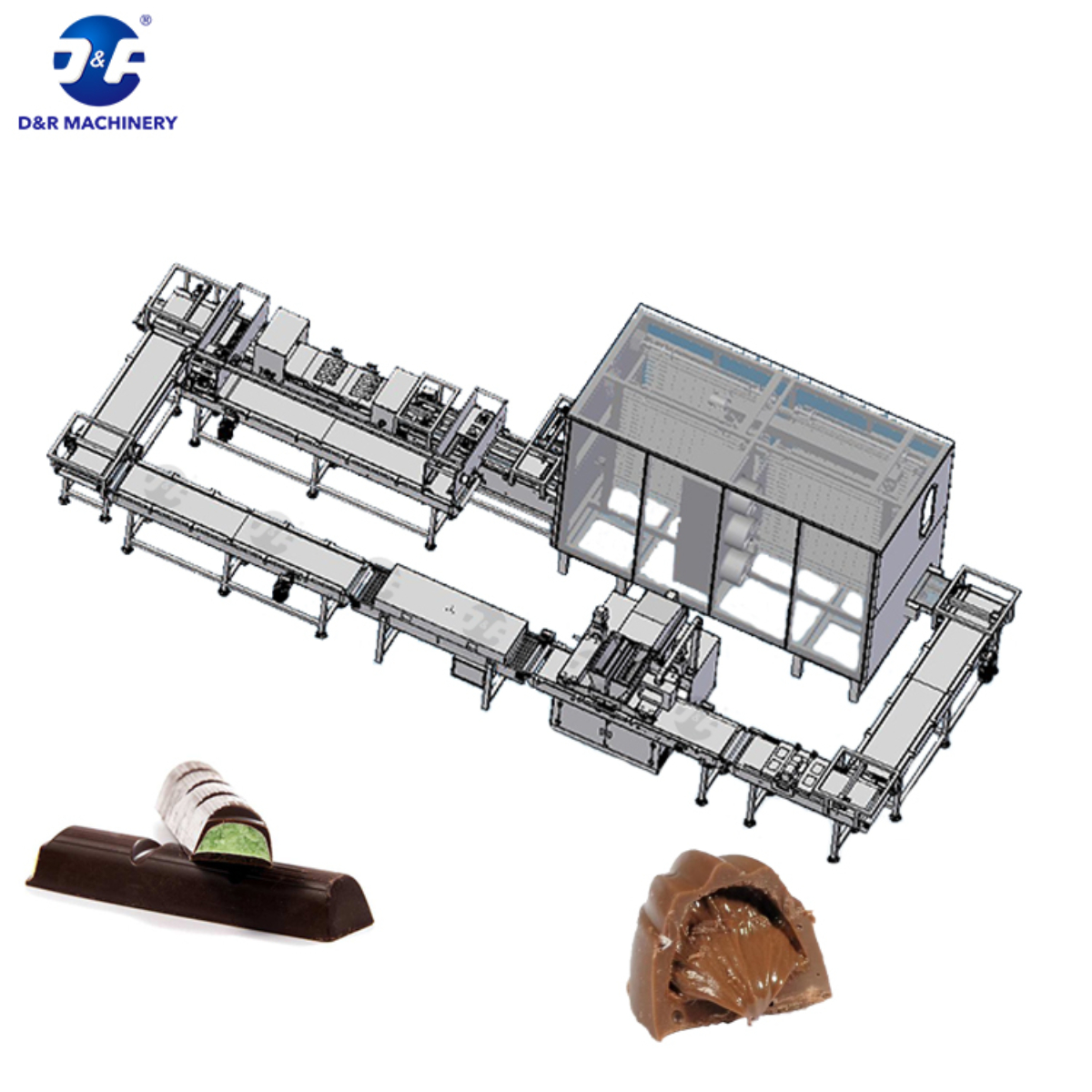

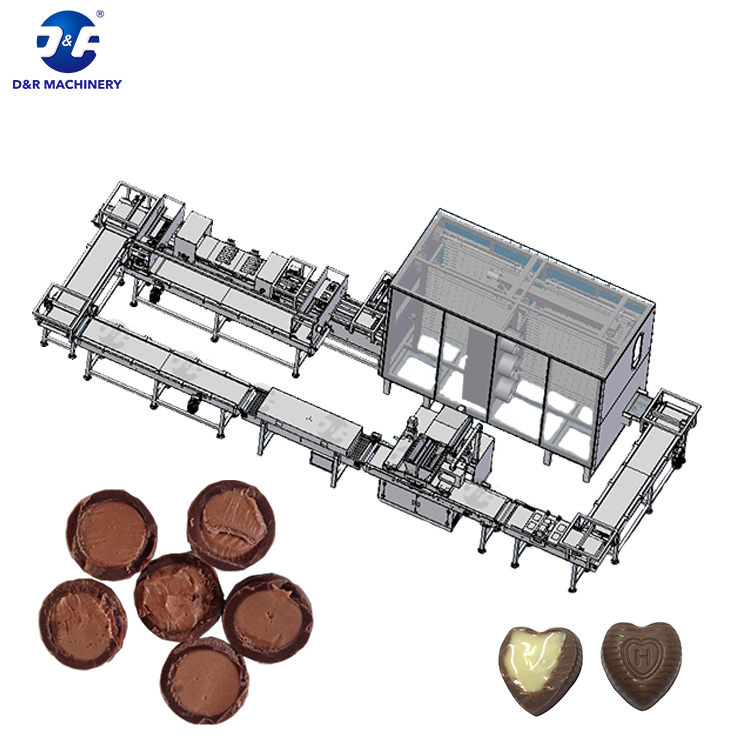

One Shot Chocolate Depositing Line

D&R Machinery

D&R one shot depositing line especially producing center filling chocolate.With high quality,easy operation,working reliable,with high output.

Leave An Inquiry

Description

One Shot Chocolate Depositing Line

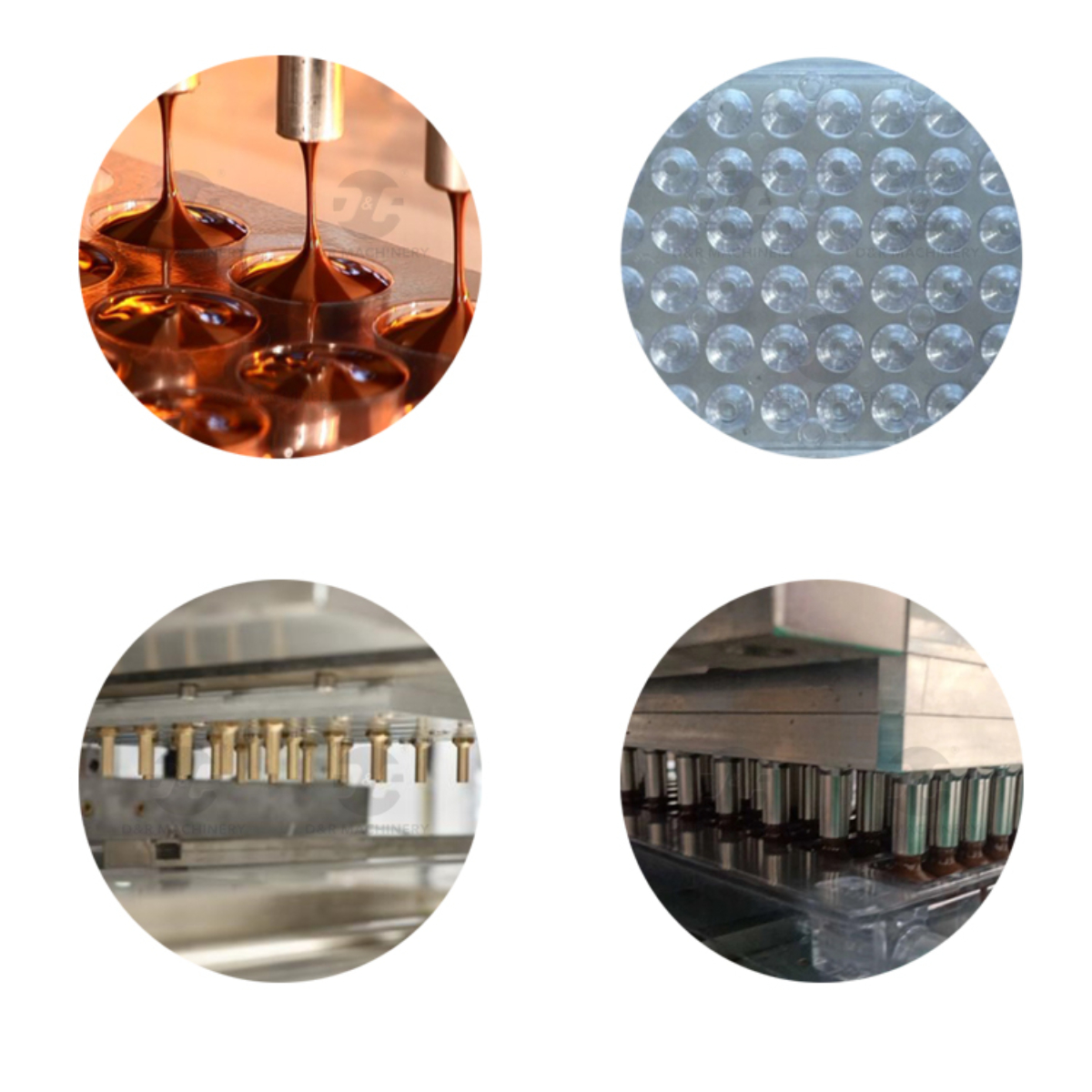

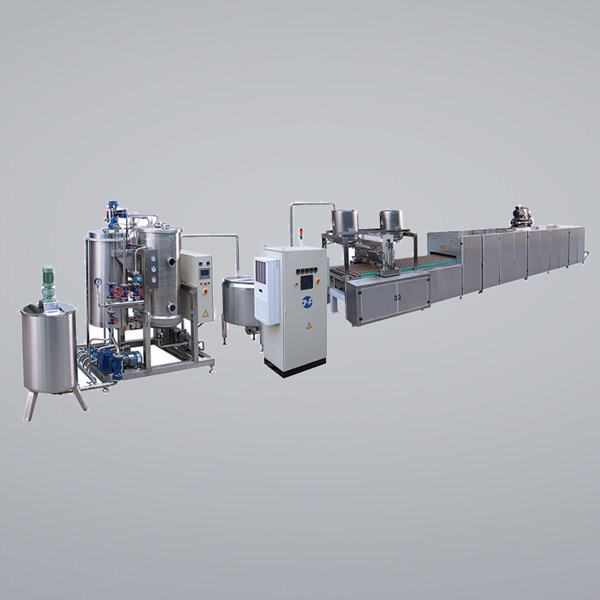

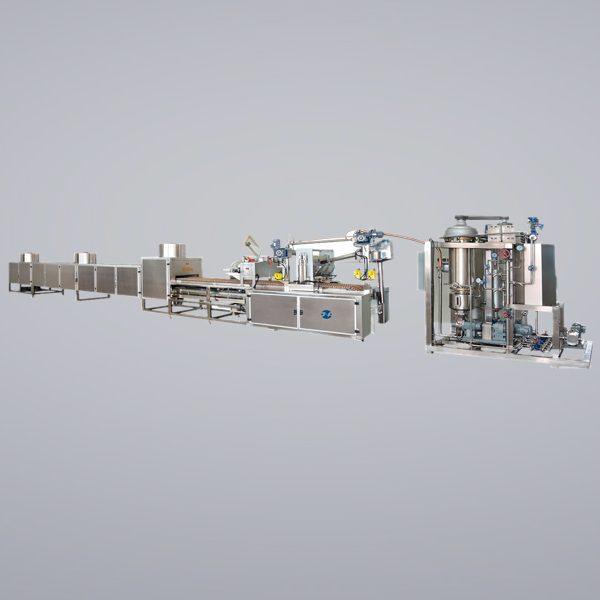

The depositor can make plain chocolates,two colors chocolates,crushed nuts or crispy rice mixed chocolates(if there is a mixer on the top of the hopper) and chocolate bars with center filling.

The depositing machine includes: one depositor with two hoppers(two parts) and it is driven by two servo motors and it can lift, the hoppers are jacket and keep warm by warm water, one belt conveyor under the depositor. The belt is also driven by servo motor, so the depositor can produce chocolate bars with center filling.Electric cabinet and hot water tank is under the conveyor. There is also a vibrator under the belt.

|

Capacity (kg/h) | 200-300(depend on the product weight) |

| Depositing Speed (mould/min) | 10-18 | |

| Weight (kg) | 5500 | |

| Dimension (mm) | 11000*4000*2500 |

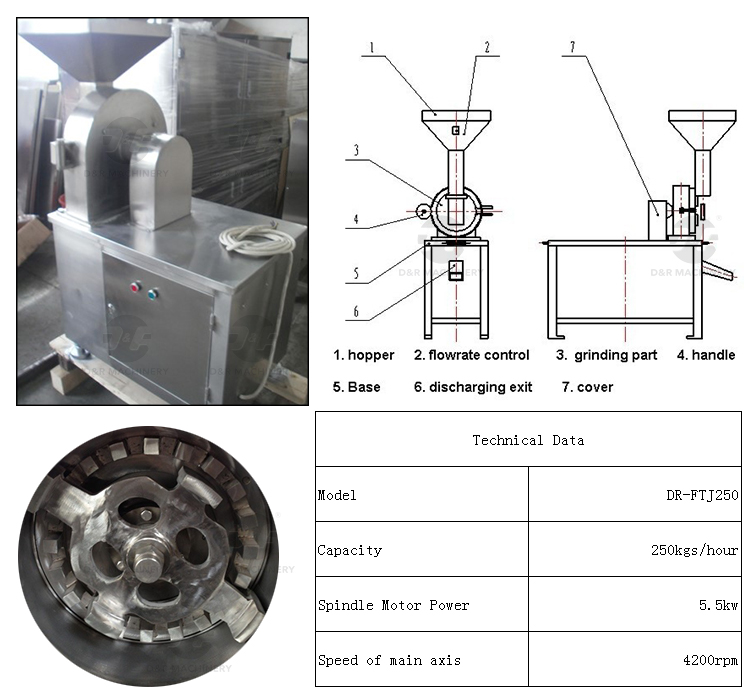

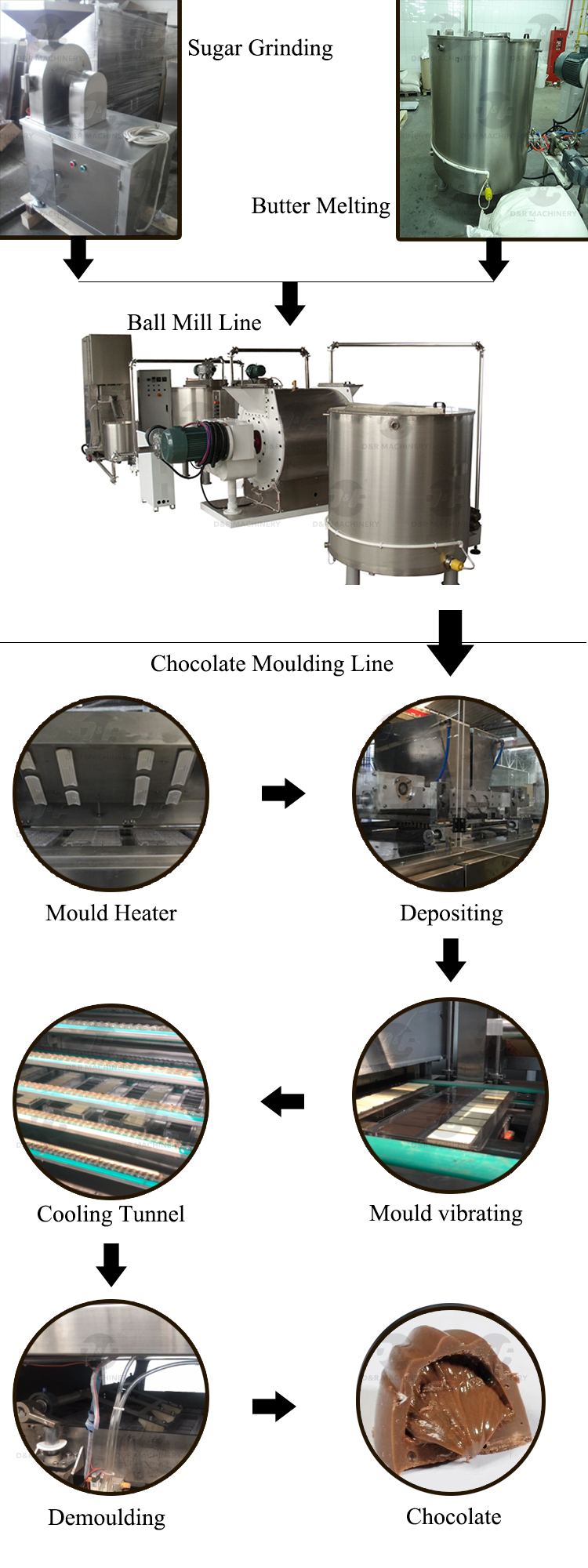

Sugar Grinding Machine

This machine is for grinding sugar to be sugar powder as required. The max. capacity is 250kg/hour. To put one bag of sugar in hopper.There are screws under the hopper which will send sugar to the grinding device,after grinding, there will be a filter and the sugar powder will flow to the bag and the big grains will be ground again.Fineness degree before grinding is 0.5-2mm and after grinding is 20-120 mesh.All are ss304.

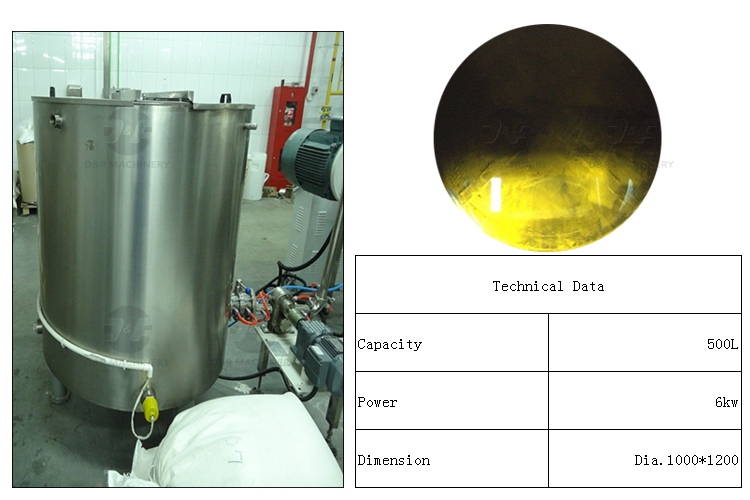

Cocoa Butter Melting Tank

The main material of chocolate is cocoa butter, and it is usually in solid.Before the chocolate material is put into the refiner/conche,the melting process is needed.Further more the coco fat melting tank can extend the life of refiner/conche.

Our cocoa butter melting tank is water jacket. The jacket tank and top cover are ss304.

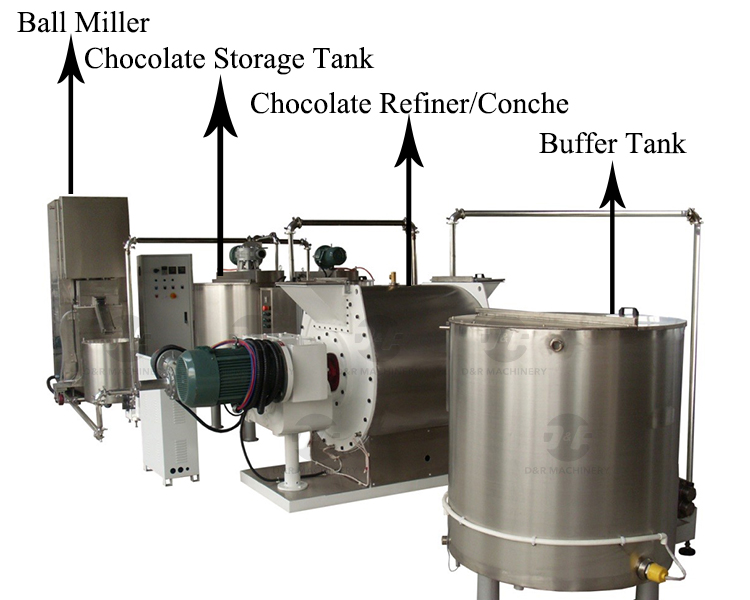

Ball Mill Line

This machine is used for fine grinding the chocolate paste material.It is a special machine for fine milling chocolate mass and its admixture. Through the impact and friction between the material and the steel balls inside the vertical cylinder, the mass is fine milled into the required fineness.

The frame of the main machine is iron with paint, covers are ss304, ,tank is stainless steel 304.The impellers are Gcr15 steel and balls are bearing steel after heat treatment,the balls are 5mm,it is about 180kg balls in each machine. The shaft is Cr40 carbon steel.

The power of gear motor is 15kw and heater of hot water is 8kw.

Chocolate Refiner/Conche

There is ventilating fan or a hopper on the top of tank , surface cover is carbon steel with paint or ss304 shell.The material of the lining bars, scrapers are 65Mn after heating treatment, it can prolong their lives. The base and gearbox are cast iron, so it will be more stable. The jacket tank is iron and heated by electricity.

Ball Miller

This machine is used for fine grinding the chocolate paste material.It is a special machine for fine milling chocolate mass and its admixture. Through the impact and friction between the material and the steel balls inside the vertical cylinder, the mass is fine milled into the required fineness.

The frame of the main machine is iron with paint, covers are ss304, ,tank is stainless steel 304.The impellers are Gcr15 steel and balls are bearing steel after heat treatment,the balls are 5mm,it is about 180kg balls in each machine. The shaft is Cr40 carbon steel.

The power of gear motor is 15kw and heater of hot water is 8kw.

Chocolate Tempering Machine

Advantage

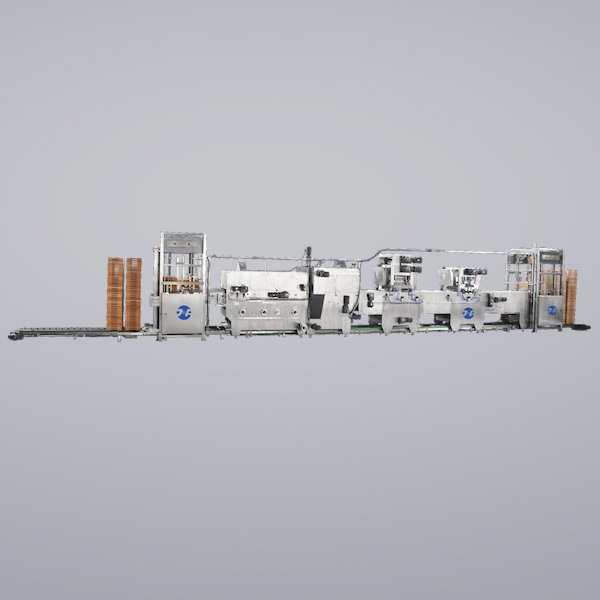

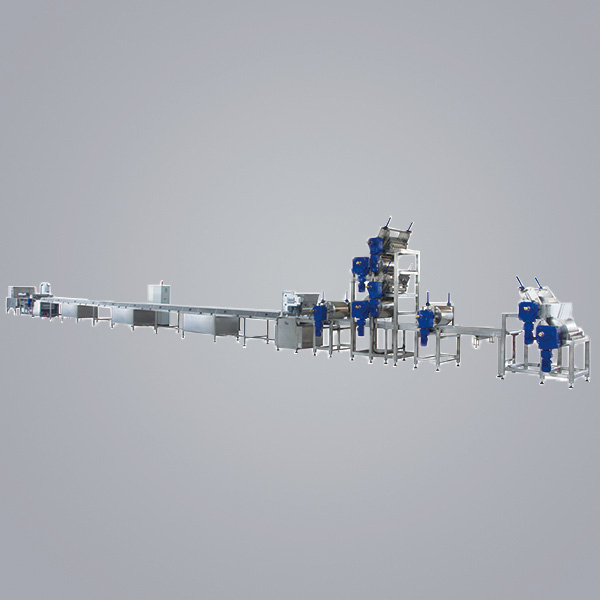

1.Full automatic PLC controlled,highly stable and reliable. Servo system not only minimize the maintenance cost and contamination to products, but also realize a more stable and bigger center filling.

2.There are a lot of add-on devices can be attached to this production line, such as Auto Biscuits Feeder, Auto Wafer Feeder, Auto Sprinkler,etc. Customers can choose these add-on devices accordingly and add or change the add-on devices for new product whenever needed.

3.There are single depositor,double depositor or more to meet different product production need.

4.To produce different kinds of chocolate products, you only need to change a depositor or the chocolate syrup distribution plate that used with the depositor.

5.Food grade 304 stainless steel used.

6.One click setting for easy and quick cleaning.

7.Minimised pipeline bends.

8.Replacement of depositing accessories can be completed in minutes.

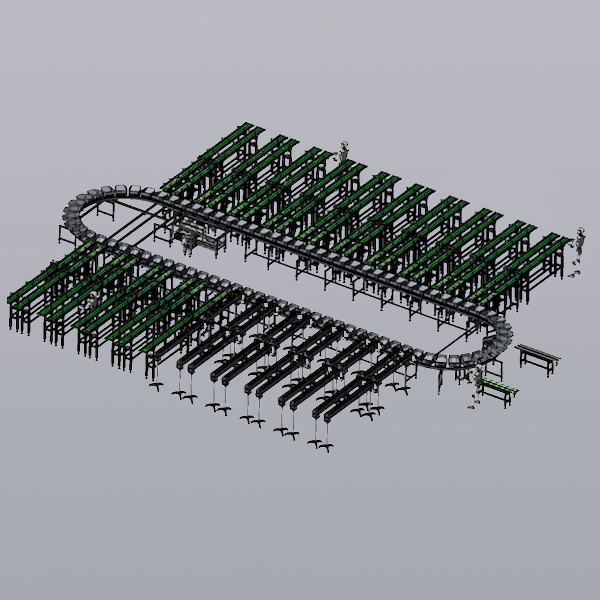

9.Factory space saved by compact structure and customised layout design.

10.Easy and fast switching among double color, spray color, center filling and etc.

TOTAL SOLUTION ,TOTAL CARE

D&R Machinery are professional confectionery machine manufacturers with over 20 years in the business operating at the highest industry standards.

We've built a reputation on engineering, designing and delivering high performance total-solution confectionery machinery to clients with absolute precision around the world.

The confectionery machinery industry is a small world, and we've slowly become leaders in innovation and creative solutions for clients from all walks of the industry. D&R Machinery has become synonymous with one word and one world only in the confectionery machinery world and that is 'total-solution', that is end to to end turn key production of the highest quality confectionery machinery in the world.

Becoming the D&R Machinery you see today starts and ends with the word 'care'. You don't become the best without a plan that ensures our clients achieve the success they desire, and at D&R Machinery it starts with care and ends with trust, reliability and innovation.

1.Q:Where are your company?

A:D&R office is located at F12, Shanshan Plaza, Yinzhou District, Ningbo, China.

D&R factory is located at Xishanli Village, Qiantong Town, Ninghai County, Ningbo, China.

2.Q:Are you direct factory?

A:We are both manufacturer and trading companiesno one knows more about our products than we do.We can provide the best quality equipment and the most affordable price, and according to your request, we can more quickly provide the corresponding service Scheme.Certainly,We welcome you to come visit our factory.

3.Q:What are your main products?

A:All kinds of chocolate making machines, candy making machines,Swiss roll and layer cake production line, cadny bar production line and their packing machines.

4.Q:Do you have gurantee for your product?

A:As a factory, no one knows more about our products than we do.We have a fairly strict standard for our products.Our products have CE certification and EAC certification.

5.Q:How can we contact you?

A:Here is contact information:

Contact company: Ningbo D & R Machinery Co., Ltd

Website:www.dr-machinery.com; www.sweetmachinery.com

Direction phone:+86 574 88304275; +86 18057458607

Fax:+86-574 87839559

Specifications

Featured Products

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message