What Is a Granola Bar Production Line?

2022-06-27 | Blog

Have you always wondered how your favorite granola bars are made? Or how do production lines work in general?

With nearly 42.68% of consumers choosing granola bars as their choice of snack over other options, it's no surprise that these tasty treats have to be produced on a large scale!

Here's a quick guide to understanding granola bar production lines and the important role that brass valves play in ensuring their functionality.

What Is a Production Line?

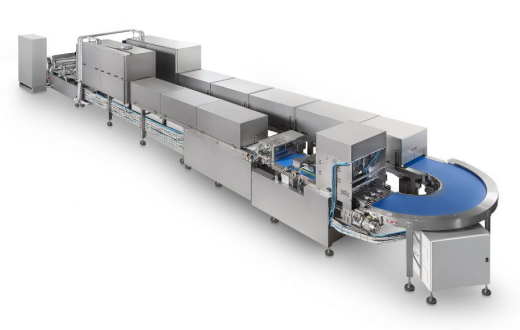

A production line is a manufacturing process that consists of a series of sequential steps. In order for products to move from one step to the next, they need to be properly conveyed.

This type of process is streamlined and efficient, as it minimizes handling and waste. When products are conveyed properly, there is less chance of defects or damage.

Using a production line for granola bars helps to ensure that they are all uniform in shape and size. This is important for both packaging and branding purposes.

How Are Granola Bars Made?

Prior to the production line or packing process, the granola mix is prepared. This usually involves combining oats, honey, nuts, and dried fruit. Making the actual granola bars can take anywhere from minutes to hours, depending on the recipe.

Some of the most common commercial granola bars are produced with ingredients like chocolate, peanut butter, and yogurt.

After the granola mix is prepared, it needs to be cooled so that it can be cut into bars without crumbling. Once it has reached the desired consistency, the production process can begin and the granola mix will be poured into a mold.

The Granola Bar Production Line Process

There are typically four steps in a granola bar production line:

1. Mixing

2. Extrusion

3. Cutting

4. Wrapping

Let's take a closer look at each step:

Mixing

The ingredients for granola bars are mixed together in large batches. The proportions of each ingredient will vary depending on the recipe.

Extrusion

The mixture is then extruded into long strips. A die is used to determine the desired shape of the granola bars.

Cutting

The long strips are then cut into individual bars. This step is typically done by a machine that uses cutting blades.

Wrapping

The granola bars are then wrapped in foil or cellophane. This helps to keep them fresh and prevents them from drying out.

Having this set of determined steps in the granola bar production line process helps to ensure a quality product that is consistent in both taste and appearance.

What Can Affect the Granola Bar Production Line?

There are a few things that can affect the granola bar production line and throw off the entire process. One of the most common problems is conveyor belt jams.

If a conveyor belt jam occurs, it can cause the granola bars to pile up and become misshapen. This can ruin their appearance and make them difficult to package properly.

Another problem that can occur is a misalignment of the cutting blades. If the blades are not aligned properly, they will not cut the granola bars evenly. This can result in uneven or jagged edges.

Both of these problems can be avoided by regularly inspecting and maintaining the production line. It's also important to use high-quality parts, such as brass valves.

The Importance of Brass Valves in Granola Bar Production

Brass valves are an important part of the granola bar production line. They are used to control the flow of ingredients and help to regulate the amount of mixture that is extruded.

If the brass valves are not properly fitted, it can result in uneven bars or even a complete stoppage of the production line. This can be costly in terms of time and money.

That's why it's important to ensure that brass valves are the right size for the granola bar production line. Using brass valves that are too small can cause blockages, and using brass valves that are too large can result in waste.

Final Thoughts

Granola bar production lines are a vital part of the food industry. They help to ensure that granola bars are consistent in both taste and appearance. The process can be affected by things like conveyor belt jams and misaligned cutting blades.

That's why it's so important to use high-quality parts, such as brass valves. Brass valves are used to control the flow of ingredients and help to regulate the amount of mixture that is extruded.

Reach out to a trusted supplier to make sure you're using the right brass valves for your granola bar production line. Doing so will help to avoid costly production line stoppages and ensure a quality product.

Back To The List

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message

Recommended Topics

Hard Candy Moulds: Best Buying Guide

If you are thinking of opening a business of molds, then you have to decide first, will it be hard candy molds or chocolate candy molds.

Warehouse Order Picking System and Its Types

It's critical to invest in a warehouse picking management system that works. Your warehouse's order-picking system can have a significant impact on the efficiency of your supply chain and overall business operations.

Chocolate Enrober Machine: All You Need to Know

A chocolate enrober machine is a device that coats candy or other food items with a layer of chocolate.It typically consists of a belt or conveyor system that moves the product through a tank of melted chocolate, depositing a thin layer of the chocolate onto the product as it moves.