Hard Candy Machine: An Ultimate Buying Guide

2022-05-24 | Blog

There are different machines to make each different type of confectionery that can be found on the market today. Confectionery is the art of making candy and different types of foods that are rich in carbohydrates and sugars. Hard candy is also known as boiled sweets in certain places of the world. Because hard candy is nearly 100% sugar by its weight, a specific type of machine is needed to produce it successfully.

Hard Candy Machines

There are different types of machines involved when making hard candy or boiled sweets. Each machine has been designed to be responsible for a different part of the finished product. There are 14 or more basic machines that are used to make hard candy. Consider the following hard candy machines that are used today.

Common Hard Candy Machinery

- Continuous Based Vacuum Batch Cooker

- Rotating Kneading Machines

- Batch Forming and Sizing Candy Machine

- Sweet Forming Machines

- Candy Forming Machines

- Auto Wrapping Machines

- Auto Pillow Packing Machines

- Powder Fill Machines

- Cooling Conveyors

- Forming Machines

- Drop Rollers

- Cooker

- Holding and Dissolving Tanks

- Forming Dies

Continuous-Based Vacuum Batch Cooker

The continuous-based vacuum batch cooker is responsible for cooking the hard candy. This piece of machinery is important because it produces candy that is high-quality hard candy with clarity and smoothness. Also, this machinery is important because it helps to keep all moisture variables under control, depending on the integrity mass. Depending on the model chosen, many of the processes that the continuous base batch cooker will handle are automatic and help to speed up the production process.

Rotating Kneading Machines

Making hard candy is a step-by-step process and the next step is using the rotating kneading machine. Volumes of sugar mass can be taken from the continuous-based vacuum batch cooker to cool, blended thoroughly, and kneaded with the rotating kneading machine. This machine makes sure that the distribution of solids is equal and that all ingredients are added hygienically.

The rotating needle machine makes sure that the sugar mass remains tempered with different parts that are integrated into the machine. Some of the parts that help to keep the sugar mass tempered include kneading star rollers and turning table plows that are water-cooled. This technology eliminates much of the manual mixing.

Batch-Forming and Sizing Machine

This piece of machinery is designed to be used in a variety of combinations for making hard candy in greater amounts. As a single platform electrical control panel. Also, it is usually made of metal or stainless steel for higher hygienically hard candy-making processes.

Sweet Forming Machines

Sweet forming machines are used to make a variety of hard candies. This piece of machinery requires less maintenance and it can be very reliable for the candy-making process. Depending on the model that is chosen, a sweet forming machine has many controls that can be used to manage different speeds.

Candy Forming Machines

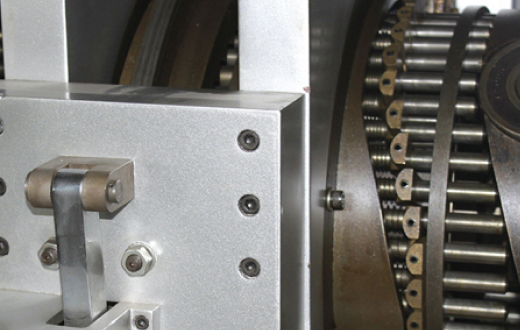

Candy farming machines are very important to the entire production process. This piece of machinery is used for forming hard candy with different thicknesses and depths in a streamlined way. There are different versions of the candy-forming machine. Newer models are fitted with reliable loaded springs and round punches that are more durable.

Hard Candy Cooling Conveyors

The hard candy cooling conveyor machine usually has different tiers, up to three or more. They are available in compact sizes that can handle high capacities. Some hard candy cooling conveyors have been designed to cool wrapped or unwrapped candies. A high-quality hard candy cooling conveyor has a hygienic design that requires little maintenance.

Auto Wrapping Machines

It is important that hard candy is carefully and efficiently wrapped for storage, transport, and retail situations. An auto-wrapping machine is able to single, double, or triple twist different sizes of hard candy. Newer models of auto wrapping machines for hard candy have optional touchscreens for easier operation. Commonly, more compact machines can wrap up to 600 pieces per minute.

Hard Candy Machine FAQ

With the right machinery, producing hard candy can be a streamlined and easier process. There are several steps involved during the production, and these are some FAQs about hard candy machines.

What Are All of The Hard Candy Machine Components?

There are 11 basic machine components for making hard candy. Each component is very important for the production steps to be streamlined, and for reducing manual labor costs.

Basic Machine Components

- Sugar Dissolver

- Conveyor

- Ingredient Mixer

- Basic Pigment Tank

- Pigment Mixer

- Secondary Conveyor

- Depositor

- Cooling and Tempering

- Demolding

- Third conveyor

- Dryer

What are the Basic Steps Made to Produce Hard Candy Efficiently?

It's important to know that the initial point of the hard candy-making process is the feeder. The feeder is where you introduce the raw ingredients for additional treatment and processing. This step may be different depending on the feeder model chosen.

The next steps include the mixing chamber where all the ingredients are mixed and each batch is mixed in a uniform way. Then there is the melting chamber. This stage of hard candy production is where all the ingredients are melted, and to ensure that the semi-solid state is essentially uniform.

Temperature is very important throughout the entire process, but it is especially vital during the melting chamber stage.

After the melting chamber process, the candy formation takes place. This involves different roles for the hard candies. After hard candies have been molded, it goes into the cooling chamber. It helps the candy to become hardened to its molded shape. The cooling chamber adds to the quality and condition of the end product.

After the hard candies have been cooled, each candy goes into the sorting chamber to ensure only the highest quality heart candies are processed and delivered for retail.

There are several other auxiliary steps that can be added to make the end product as unique as possible. Other steps can include the packing chamber, utilizing different control panels, food-grade conveyor belts, and printing machines. This includes packing & sorting machines for hard candy production.

Is it possible to produce unique shapes of hard candy?

It is possible to produce unique shapes of her candy. It strictly depends on the type of mold you are using, the designs needed, and the different specifications that are being used.

Are all hard candy machines nearly fully automatic?

There are different models of hard candy production machines available and many of the models have features that make it seem as if the process is fully streamlined, with minimal labor needed. However, there are some manual hard candy machines available on the market. It is important though that labor costs can go up when using these types of machines.

Back To The List

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message

Recommended Topics

Hard Candy Moulds: Best Buying Guide

If you are thinking of opening a business of molds, then you have to decide first, will it be hard candy molds or chocolate candy molds.

Warehouse Order Picking System and Its Types

It's critical to invest in a warehouse picking management system that works. Your warehouse's order-picking system can have a significant impact on the efficiency of your supply chain and overall business operations.

Chocolate Enrober Machine: All You Need to Know

A chocolate enrober machine is a device that coats candy or other food items with a layer of chocolate.It typically consists of a belt or conveyor system that moves the product through a tank of melted chocolate, depositing a thin layer of the chocolate onto the product as it moves.