Candy Packaging Machine: All You Need to Know

2022-05-28 | Blog

It is a machine that is used in packaging or wrapping candies in the confectionery industry. The candy packaging machine has a variety of options for packaging, including wrapping and assembling the candies in containers or pouches.

Importance of the Candy Packaging Machine

Time-Saving

The candy packaging machine saves a lot of time. Manually wrapping and packaging the items is a hassle and very time-consuming. This machine brings ease and saves time.

Merchandise Appeal

The candy packaging machine increases the appeal of the confectionery. This machine will enhance the look of your merchandise. This will also help your items stand out on the shelf and attract customers' attention.

Prevents Contamination

The candy packaging machine also prevents the contamination of the confectionery. Enclosing the candies will protect them from harmful environmental factors like dirt, moisture, and ultraviolet rays.

Increased Efficiency

The candy packaging machine makes the whole process of packaging fast, consistent, and efficient compared to manual wrapping, which is slow and inconsistent.

Increase Manufacturing Capability

A candy packaging machine enables one to pack more candy per unit of time. However, the fully automated candy packaging machines have the greatest candy packaging rate.

Components of a Candy Packaging Machine

Candy packaging machines are made up of various parts that work together to make them efficient and productive. Furthermore, each component has a specific purpose, yet they all work together to provide a smooth operation.

The following are the primary components:

Electricity Unit

This component powers the candy packaging machine, which supplies electricity to all of the other parts of the machine to keep it functional.

Feeder

This part of the candy packaging machine packs the ready candies into the packets or packaging. Various kinds of packages are also fed to the candy packaging machine in the feeder device.

Labeling Unit

It is essential to have a label on the product. A label provides information about the product, the manufacturing country, expiry date, price, and ingredients. Not only that, labeling enhances the look of the candy as well. It will attract the buyer and magnify the product's appeal.

Sealing Unit

This part of the candy packaging machine seals the candy and also prevents air from entering the package, which is eventually very critical for maintaining the quality of the product.

Control Panel

A candy machine also comprises a programmable logic controller (PLC) and an interactive human-machine interface (HMI), which makes it simple to monitor and control the candy packaging machine from a single location.

Conveyors

This component will aid in the movement of items from one machine portion to another.

Lubrication Unit

Many moving parts in candy packaging machines are subject to wear and strain. For this reason, the lubrication system lubricates these components to lessen the amount of friction they cause. This will increase the lifespan of the candy packaging machine while cutting maintenance expenses.

Features of a Candy Packaging Machine

Here are some of the greatest characteristics of these machines:

- The body of the candy packaging machine, made of stainless steel, maintains the hygiene levels because it is easy to keep it clean.

- The machine has the feature that when there is no candy, there is no packaging, which reduces the loss.

- The candy packaging machine with PLC with HMI provides easy operation and parameters of packaging.

- The automatic feeding system of the candy packaging machine delivers excellent packaging efficiency.

- It also has the capability of varying bag lengths.

- The candy packaging machine has the feature that the error will be displayed by a self-diagnostic function.

- The digital input for varied cutting locations is tracked by a highly sensitive optical photocell that records eye markings.

- The machine has certifications including CE, ISO, and cGMP.

- The candy packaging machine has temperature PID controllers that are ideal for a variety of packaging materials.

- The candy packaging machine has a position stop feature that avoids waste and preserves the cutting jaws in the absence of adhesive.

- The candy packaging machine provides smooth rolling of the film material by using a stable roll film.

Candy Packaging Machine Materials

Candy packaging machines can be used with a wide variety of materials. The sort of material being used is determined by a number of criteria, including the type of candy, storage, etc.

These are some examples of these materials:

- Aluminum film

- Poly Lactic Acid [PLA]

- Wax paper

- Cellophane

- Cast Polypropylene [CPE]

- Polyester [PE] film

- Polyvinyl Chloride [PVC] films

- Paper film

- Composite film

Key Considerations for Buying a Candy Packaging Machine

- The material's cost

- The material's texture

- The product's shape

- The film's inability to stay away from sweets

- The type of item you're packaging

- candy packaging machine type

- Qualities of release

- Tightness of twist

- The noise or crinkle produced by the substance

Various Types of Candy Packaging Machines

The candy packaging machine market is full of different machines, each one with its own style and features.

The following candy packaging machines are available on the market.

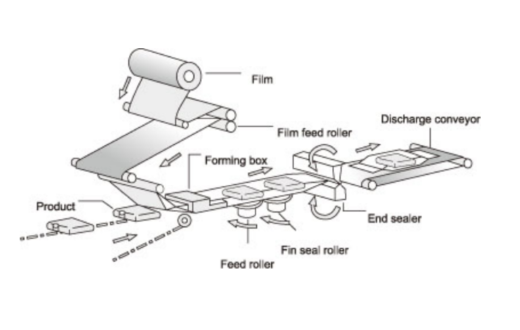

Flow Candy Packaging Machine

This is a horizontal candy packaging machine that accepts items and packs them with printed or transparent film. The result is sturdy yet flexible, with a vertical back seal and horizontal seals on the top and bottom.

Folding Candy Packaging Machine

This is a machine that uses paper film or aluminum foil to encapsulate items without utilizing a thermal seal. It's ideal for packaging heat-sensitive items. Furthermore, they have a solid and tight grip on the items.

Twisting Candy Packaging Machine

This is a machine that twists both ends of the product packaging material to produce an enclosure. As it requires a strong structure, cellophane is the optimum material for this technique. On unpackaging the item, the cellophane material will make cracking sounds. Confectionery manufacturers use twist candy packaging machines to pack individual items rapidly.

Foil and Band Candy Packaging Machines

This is a machine that performs two procedures in order to produce the best packaging results. It starts by coating a product in aluminum film and then wrapping it in paper bands. Confectionery and chocolate bars can be wrapped in candy foil and band wrappers.

Candy Overwrapping Packaging Machine

This is a candy packaging machine that uses a single product or a group of objects in the process. Following that, it will use folding and sealing sequence techniques to create a pack with a full wrap. Cellophane, polyethylene and polypropylene, are all materials that may be used in a candy overwrapping packaging machine. This machine will also manufacture high-quality packaging solutions.

Back To The List

LEAVE AN INQUIRY

Thanks for your inquiry. Our expert will reply in 24 hours.

Send Message

Recommended Topics

Hard Candy Moulds: Best Buying Guide

If you are thinking of opening a business of molds, then you have to decide first, will it be hard candy molds or chocolate candy molds.

Warehouse Order Picking System and Its Types

It's critical to invest in a warehouse picking management system that works. Your warehouse's order-picking system can have a significant impact on the efficiency of your supply chain and overall business operations.

Chocolate Enrober Machine: All You Need to Know

A chocolate enrober machine is a device that coats candy or other food items with a layer of chocolate.It typically consists of a belt or conveyor system that moves the product through a tank of melted chocolate, depositing a thin layer of the chocolate onto the product as it moves.